Curved surface printing, now without boundaries

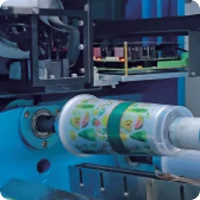

Industrial level, designed specifically for 360 one pass rotary printing on bottles

Industrial level, designed specifically for 360 one pass rotary printing on bottles

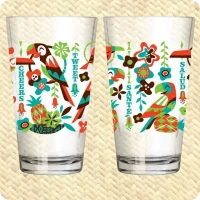

A revolutionary fusion of high speed and versatility. A single scan can achieve 360° high-definition color single pass printing and embossing effects on the surfaces of various cups, jugs, and conical bottles, breaking through the limitations of materials and shapes and elevating production efficiency and creative possibilities to a whole new level.

* Advanced spiral inkjet printing solutions are designed for high-quality digital printing on cylindrical and conical objects such as insulated cups and milk tea cups.

* Highly automated assembly line production processes reduce manual intervention, improving production efficiency and stability.

* Single-color, multi-color, and embossed patterns can all be applied directly to the bottle.

* Compared to traditional printing methods, UV single-pass printing requires no plate making and features 8 workstations for higher efficiency.

* High speed: 300-600 prints/hour

* Up to 15mm inkjet printing height, achieving perfect printing results on curved surfaces.

* Internal ink circulation within the printhead makes maintenance easier and extends printhead life.

* Simple operation with a user-friendly interface.

Revolutionizing the boundaries of printing: a cup, a moment, can be printed.

Revolutionary UV Single Pass printer technology brings you the ultimate digital printing experience

No need to make plates, just import pictures and print.

Printing

flexibility

Different color patterns need to be made separately, which increases manpower, material resources and storage.

CMYK+W multi-color printing, or single color printing, optional.

Multi-color

direct printing

Only single-color printing is possible at a time.

Printable flat and embossed effects.

Printing

effect

Only flat effect.

Less hca sol vent use and waste water discharge.

Environmentally

friendly

The use of chemical solvents and wastewater discharge are high.

In the field of industrial-grade single-pass digital printing, the printhead is not only a core component but also the soul that determines production efficiency and output quality.

We perfectly combine high-performance industrial printheads with our CupJetPro -SP360 UV Single-pass 360 Cup Printers to bring you the ultimate printing experience.

Greyscale levels printing

reproduction and durability

While achieving high-speed printing, it also ensures superior color performance. The high-precision inkjet system combined with optimized color management software allows for accurate, vibrant, and naturally transitioning full-color images on a variety of cups in a single print. Whether it’s complex gradient patterns or delicate brand logos, it delivers high fidelity and outstanding visual impact.

Oil-based Single Pass UV ink with its non-VOC formula, significantly reduces its environmental impact, meeting increasingly stringent international environmental standards. green, safe, and harmless, protecting your health.

Every user’s product size, height, and printing needs are different. Novix has a professional technical team and engineers who can tailor a complete, intelligent, and automated printing solution to your specific needs.

Contact the Novix team now!

Good products are revealed in the details.

| Print head | Industrial piezoelectric printhead |

| Technology | MEMS/ POD technology |

| Ink recirculation | Ink recirculation through all channels |

| Printhead life | Piezoelectric Drive durability, more than 106 billion inkjet times |

| Greyscale | Greyscale levels printing |

| Nozzles Resolution | 300npi(2 color/head)/ 600npi(1 color/head) |

| Number of nozzles | 639nozzles(2 color/head)/1278nozzles(1 color/head) |

| Temperature control | Build-in temperature sensor |

| Jetting frequency | 12kHz/3drops |

| Printhead Protection Technology | Auto carriage/printhead anti-scratch kit |

| Printer name | 360° UV Single Pass Cup Printer |

| Model | CupJetPro -SP360 |

| Printing mode | CMYK, CMYK+W, Single color |

| Printing station | 8 stations |

| Printing width | Max 170mm |

| Max cup diameter | 120mm |

| Print Speed | 300 ~ 600 pcs/H |

| Media Release device | Fully automated operation |

| Media Take up device | Take up tray *Optional |

| Control syetem | Novix Single Pass Control software, pre-installed in integrated computer on machine |

| RIP Software | RIIN software with color management (With ink consumption/ cost auto calculation) |

| Remote control software | Pre-installed in integrated computer on machine |

| Other option | Software interface secondary development available |

| Variable data editing software available | |

| I/O Interface, robot controlling conection support |

| Ink type | Oil-based Single Pass UV ink (Non-VOC) |

| Ink supply | Continual ink supply system (CISS); Intelligent constant sub-ink tank pressure |

| Ink filter | Ink filtration system available to filtering oversized particles |

| Temperature | 15℃~ 30℃ (59ºF~86ºF), Humidity 30%-70% |

| Voltage | 220V/AC(±10%), 50/60Hz, 1KW(Max.) |

| Acoustic noise level | 70db(A) or less |

| Printer size(L*W*H) | 1600*1400*1950mm |

| Solution size(L*W*H) | 3500*2500*1950mm |

| Package size(L*W*H) | 1800*1600*2100mm |

| Net Weight of printer | 900kg |

| Gross weight | 1100KG |

| Operating system | Windows® 10 (64 bit) Recommend |

| CPU | Intel® Core™ i5, 2.5 GHz or more |

| HDD | Install space 1 GB or more; Working space 100 GB |

| Processor prefered | INTEL AMD |

| Storage | RAM>8G |

| Data Interface | Gigabit Ethernet port |

As a technological innovator in the field of round bottle printing, our printers deeply integrate the high compatibility of UV curing with Single Pass high-speed printing technology, specifically designed for 360° full-coverage printing of various cylindrical and conical bottles. By perfectly combining the flexibility and efficiency of digital printing with industrial-grade stable quality, we make seamless transitions from personalized customization to mass production a reality, opening up unprecedented creative and business possibilities for users.

It refers to the ability to complete 360° full-circle printing and instant UV ink curing in a single pass. It solves the pain point of low efficiency in UV flatbed printing and overcomes the limitation of Single Pass equipment that can only print on flat materials, achieving high-speed, high-quality output on irregular curved surfaces.

The printer is highly compatible and can print directly on irregularly shaped bottles such as plastic cups, stainless steel insulated cups, PET cups, glass cups, and conical flasks. Whether the surface is straight-walled, conical, or curved, as long as it is a rotatable cylindrical structure, it can achieve perfect printing.

Its production speed far exceeds traditional processes (such as heat transfer printing, water transfer printing, screen printing, etc.) and UV printing. Taking a typical-sized bottle as an example, it can stably produce 300-600 bottles per hour, and the speed is not reduced by the complexity of the colors, truly achieving fast delivery for small batches and cost reduction and efficiency improvement for large batches.

Whether it’s full-color printing, gradient printing, or even embossed printing, it can greatly enhance the added value of products.

It eliminates the need for plate making, film, or intermediate consumables, truly achieving digital production. UV ink dries instantly, requiring no post-processing, saving manpower and space. Main maintenance is focused on regular printhead maintenance, ensuring high stability and effectively controlling long-term operating costs.

Novix team is dedicated to research and development, striving to bring you the smartest, most convenient, most suitable, and most cost-effective printing solutions to empower your brand.

Do not hesitate to reach out. Just fill in the contact form here and we’ll be sure to reply as fast as possible.

Room 105, Tower B, Tianhui Building, No. 29, Yeqin 1st Road, Longgang District, Shenzhen, Guangdong, China

info@onepassprinters.com

+86 13302697226

Do you want to receive notifications about:

* You can cancel your subscription at anytime