Advantages

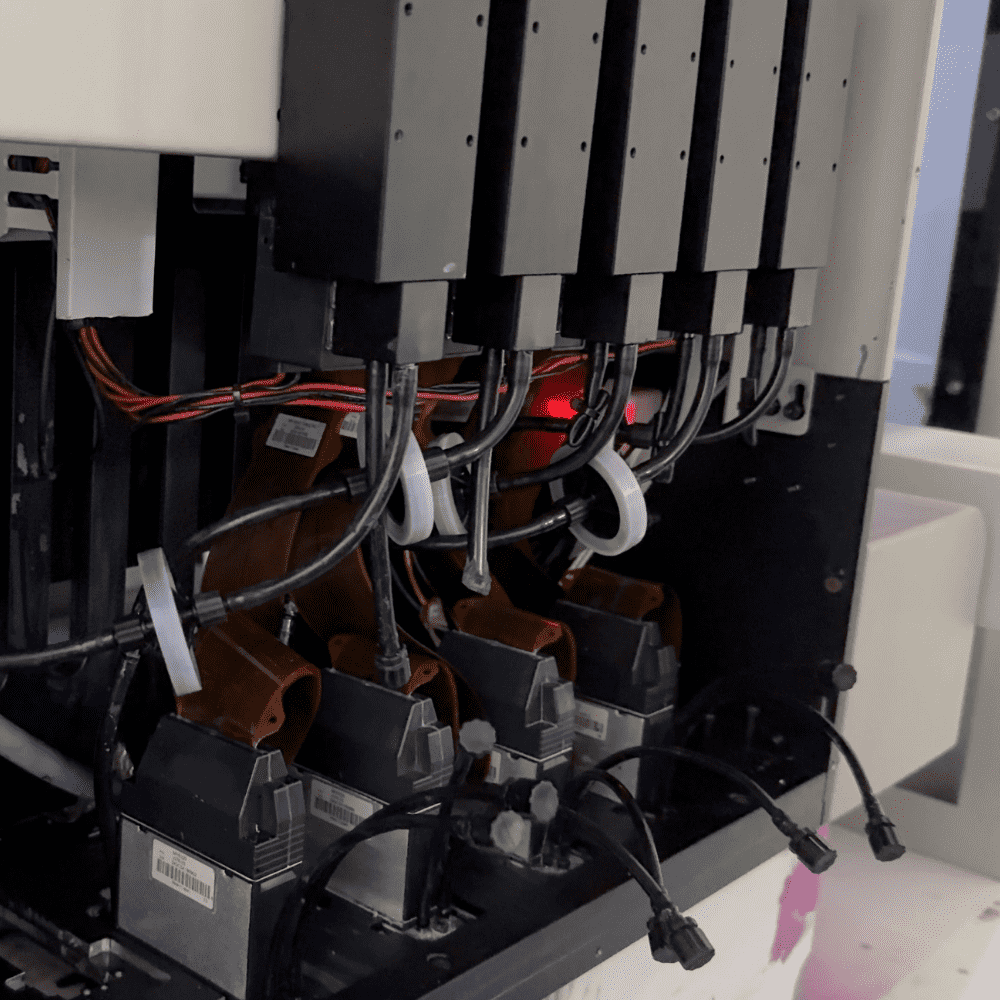

1. Industrial Ricoh G5/ G6 printhead, Piezoelectric Drive durability, more than 106 billion inkjet life times.

2. Speed: Single color: 0-120m/hrs; Multi-color: 0-25m/hrs

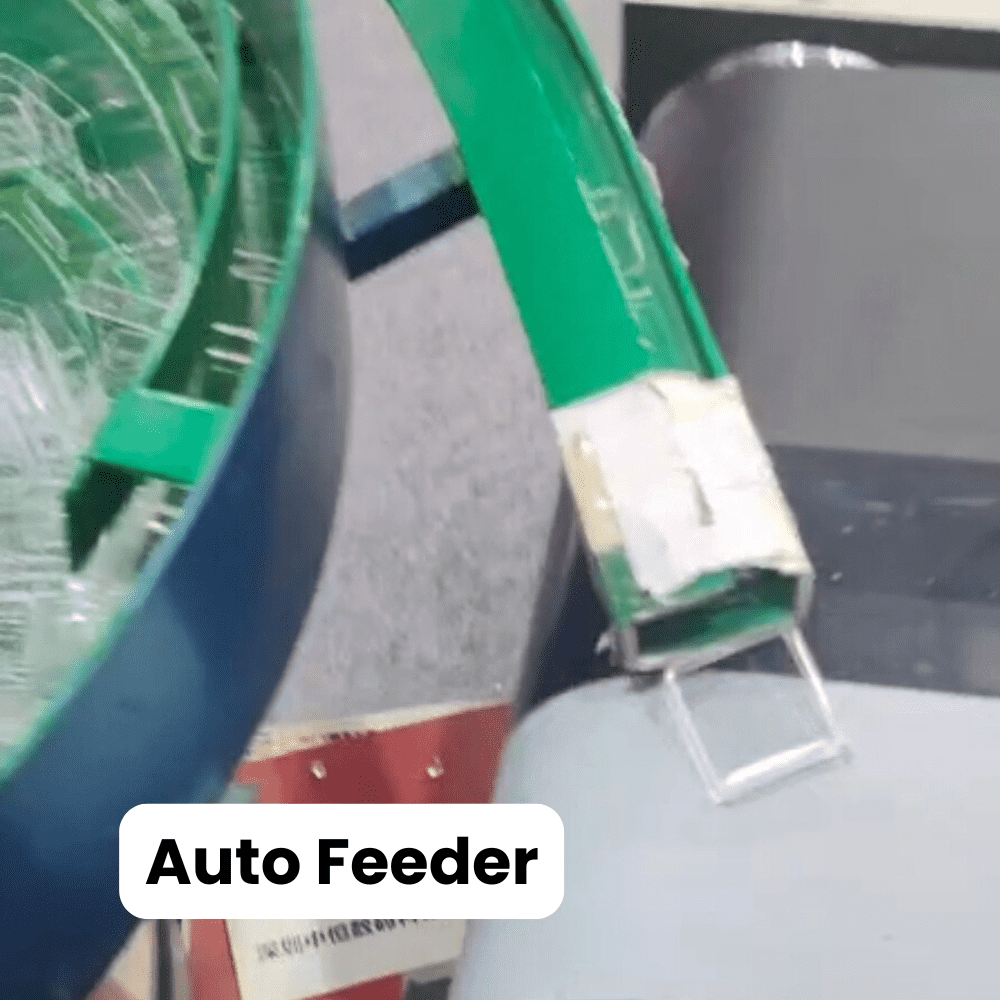

3. Automatic feeder customized available for different products, save labour cost.

4. Height memory function: The print head automatically returns to the printing height of last printing jobs.

5. Independent LED UV lamp cooling box system, better instant curing after printing

6. Plasma treatment to clean dust and increase color fastness on products

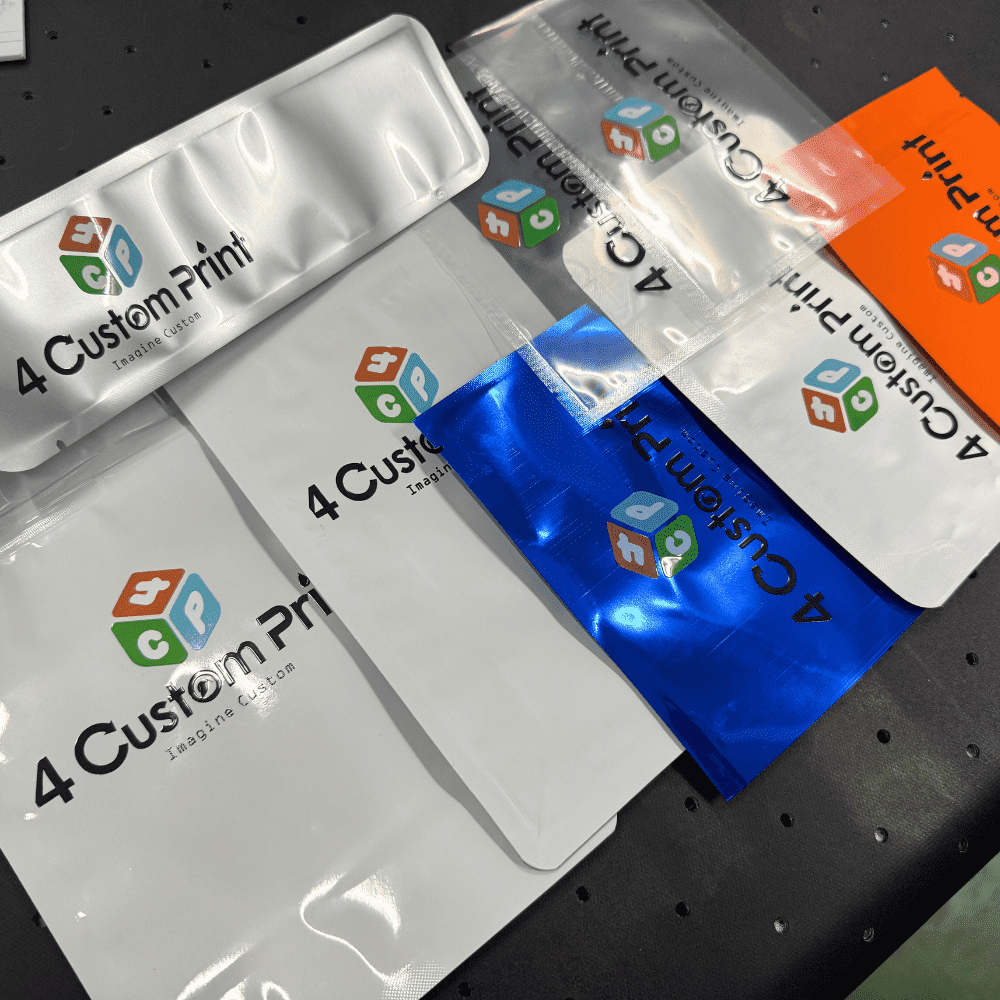

7. More compatible ink, over 200 types of ink tested for better printing quality and color reproduction on different material.

Application

PVC, PP, plastic, rubber, metal, wood, glass, hand craft, gift item etc.

| Print head | Ricoh Gen5/ Ricoh Gen6/ Kyocera(option) |

| Technology | MEMS |

| Printhead life | Piezoelectric Drive durability, more than 106 billion inkjet times |

| Ink drop Volume | Binary mode: 7pl / Grey-scale mode : 7-35pl *depending on the ink |

| Horizontal Resolution | 600dpi |

| Vertical Resolution | 200~1200dpi multiple adjustable |

| Number of nozzles | 1,280 (4 × 320 channels), staggered |

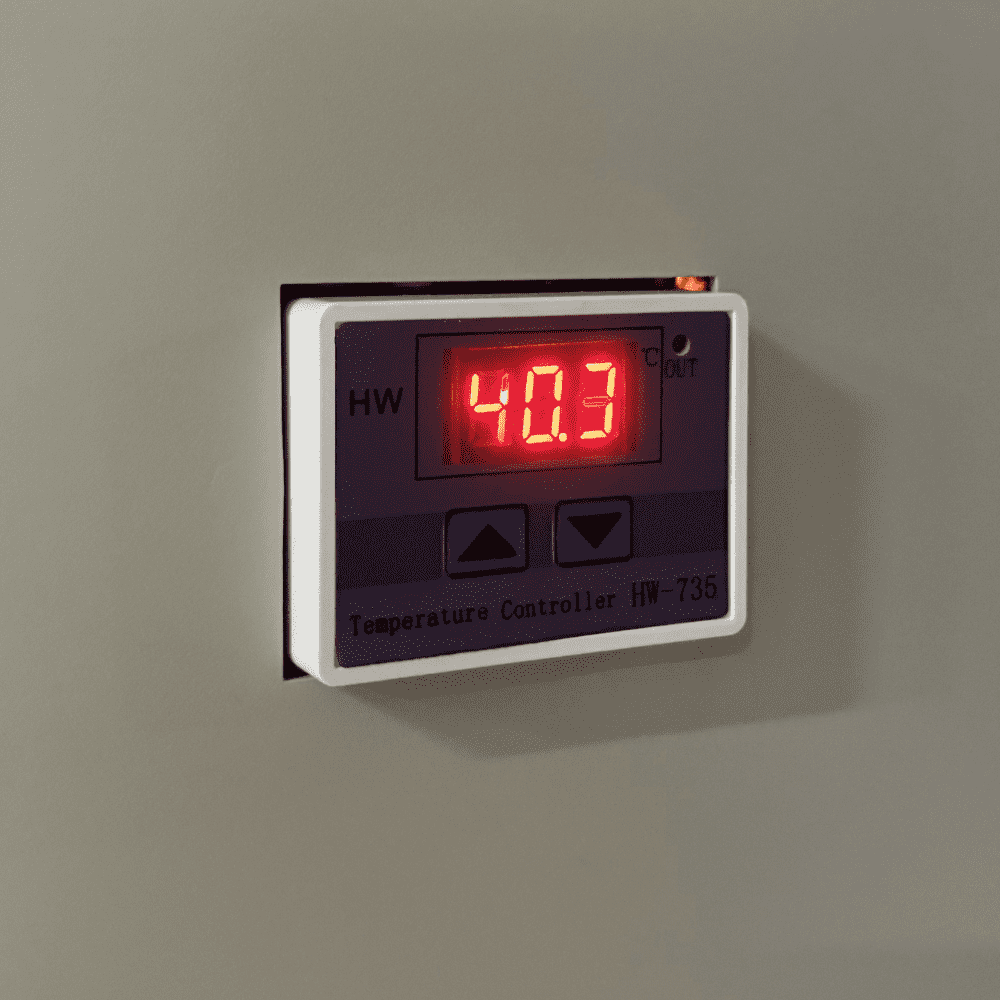

| Temperature control | Integrated heater and thermistor |

| Jetting frequency | Binary mode : 30kHz / Grey-scale mode : 20kHz |

| Printhead Protection Technology | Auto carriage/printhead anti-scratch kit |

| Maximum printing thickness | 0-150mm (Printing height customization available) |

| Printing width(mm) | 54mm/108mm/Multiple row options |

| Material width(mm) | 400mm |

| Print Speed | Single color: 0-120m/hrs Multi-color: 0-25m/hrs |

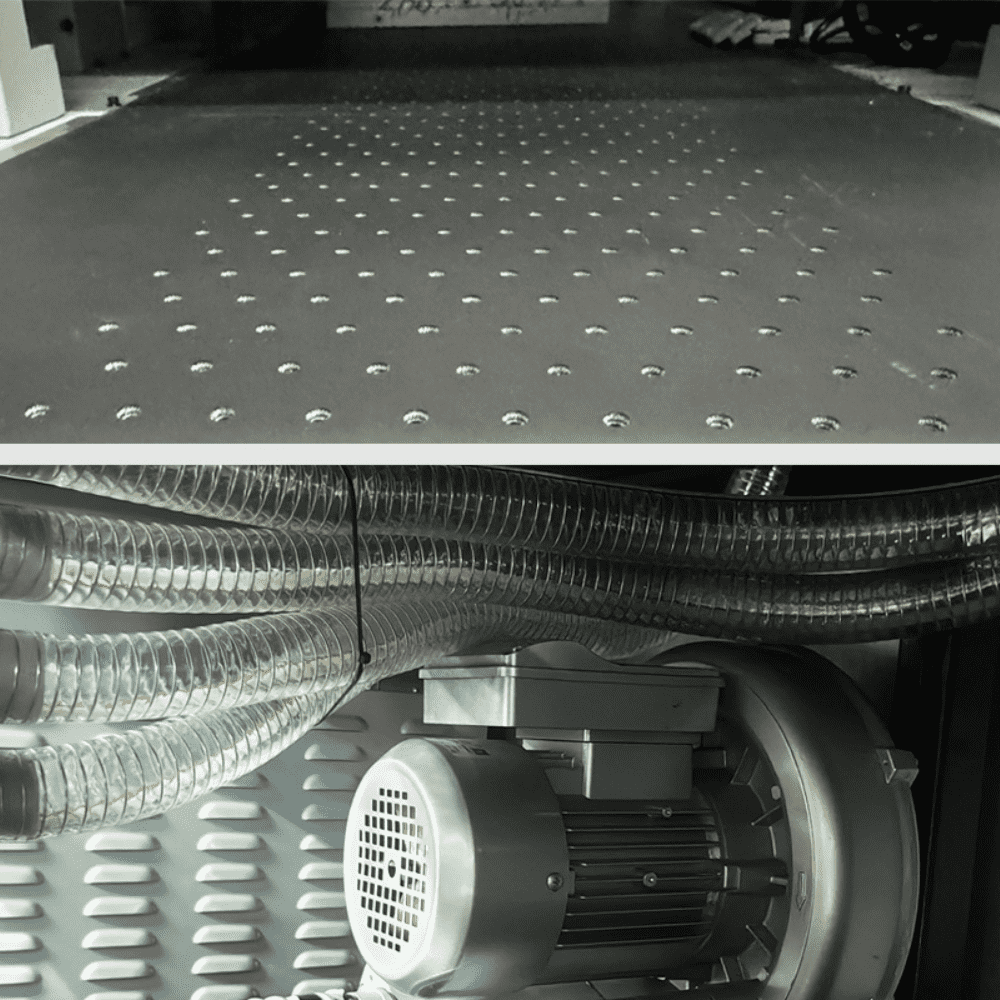

| Flatbed Type | Auto continual conveyor, Vacuum adsorption table option available |

| Media Release device | Manual feeding/ customized feeder *Optional |

| Media Take up device | Take up tray *Optional |

| X axis adjustment | Quality linear rails + Ball screws |

| Z axis adjustable | Button & manual adjustment available |

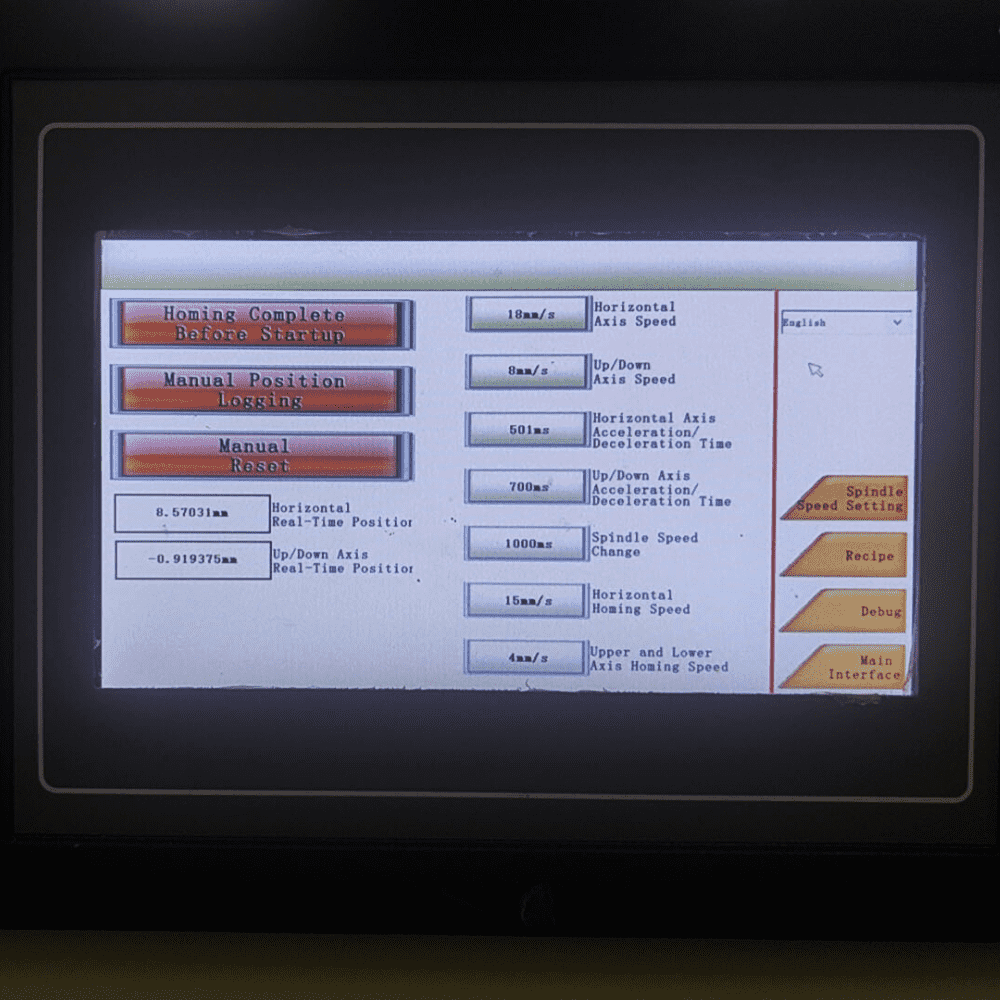

| Control syetem | Novix Single Pass Control software, pre-installed in integrated computer on machine |

| RIP Software | RIIN software with color management (With ink consumption/ cost auto calculation) |

| Remote control software | Pre-installed in integrated computer on machine |

| Other option | Software interface secondary development available |

| Variable data editing software available | |

| I/O Interface, robot controlling conection support |

| Ink type | Oil-based Single Pass UV ink (Non-VOC) |

| Color Configuration | Single color; Multi-color: Cyan(C), Magenta(M), Yellow(Y), Black(K), White (W) |

| Ink supply | Continual ink supply system (CISS); Intelligent constant sub-ink tank pressure |

| Ink filter | Ink filtration system available to filtering oversized particles |

| Ink tank | 2500ML/color |

| Protection system | Automatic ink shortage alarm system, support ink refilled during printing |

| Anti clogging of Printhead | Automatic white ink stirring system; nagative pressure ink control |

| Cleaning & Maintenance system | Automatic cleaning ink station, auto flashing and maintanence |

| Temperature | 15℃~ 30℃ (59ºF~86ºF), Humidity 30%-70% |

| Voltage | 220V/AC(±10%), 50/60Hz, 1KW(Max.) |

| Acoustic noise level | 70db(A) or less |

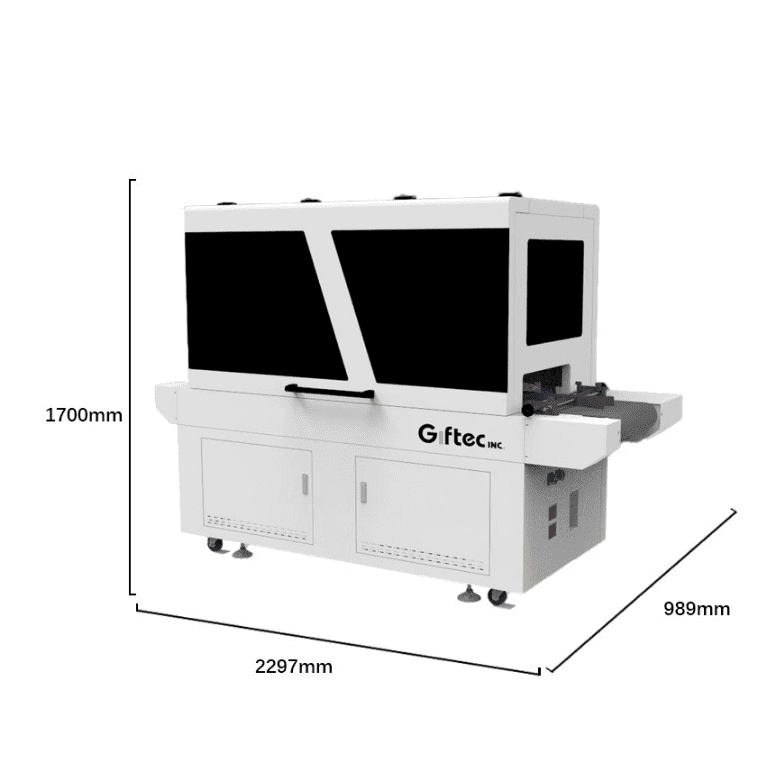

| Printer size(L*W*H) | 2297*989*1700mm |

| Package size(L*W*H) | 2500*1000*1900mm |

| Net Weight of printer | 560KG |

| Gross weight | 640KG |

| Package type | Inside foam protection, outside Ply-wood steel frame package |

| Operating system | Windows® 10 (64 bit) Recommend |

| CPU | Intel® Core™ i5, 2.5 GHz or more |

| HDD | Install space 1 GB or more; Working space 100 GB |

| Processor prefered | INTEL AMD |

| Storage | RAM>8G |

| Data Interface | Gigabit Ethernet port |

·Automatic feeder customized available for different products, save labour cost.

·Automatic plasma treatment removes dust and improves product color fastness

·Novix RIIN software with color management (With ink consumption/ cost auto calculation)

·Continual ink supply system (CISS); Intelligent constant sub-ink tank pressure

·Automatic ink shortage alarm system, support ink refilled during printing

·Automatic white ink stirring system; nagative pressure ink control

·Automatic cleaning ink station, auto flashing and maintanence

·over 200 types of ink tested for better printing quality and color reproduction on different material.

·Support variable code software installation

·I/O Interface, robot controlling conection support

Let your pattern be realized on the product

Novix upgraded Control software & RIP color management all in one output software, intelligent color management, accurate control, good color reduction, simple and clear interface, easy human-machine interaction and simple operation.

Rich and diverse product customization brings you rich business and profits

Good products are determined by details

UV One Pass Printer is a solution for every application, and is highly automatic with its consolidated experience in industrial printing, in particular in the field of digital printing, enabling gift manufacturers, printing service provider and printer distributors to respond effectively to market needs while achieving high profit margins even on small production batches.

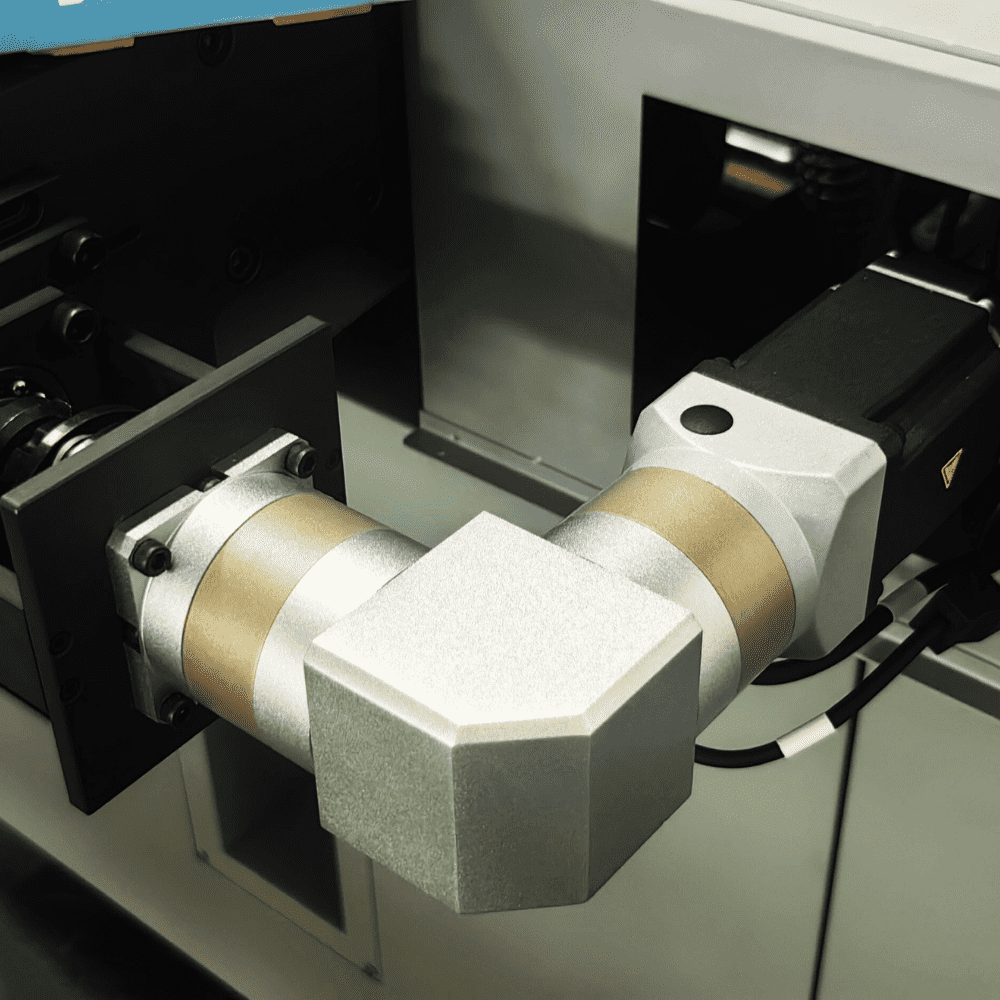

The Ricoh G6 printhead has an integrated heater and thermistor, keep the ink supply inside the printhead at a constant temperature, ensuring the printing effect, preventing clogging, and easy maintenance.

PLC touch screen control panel for user-friendly operation.

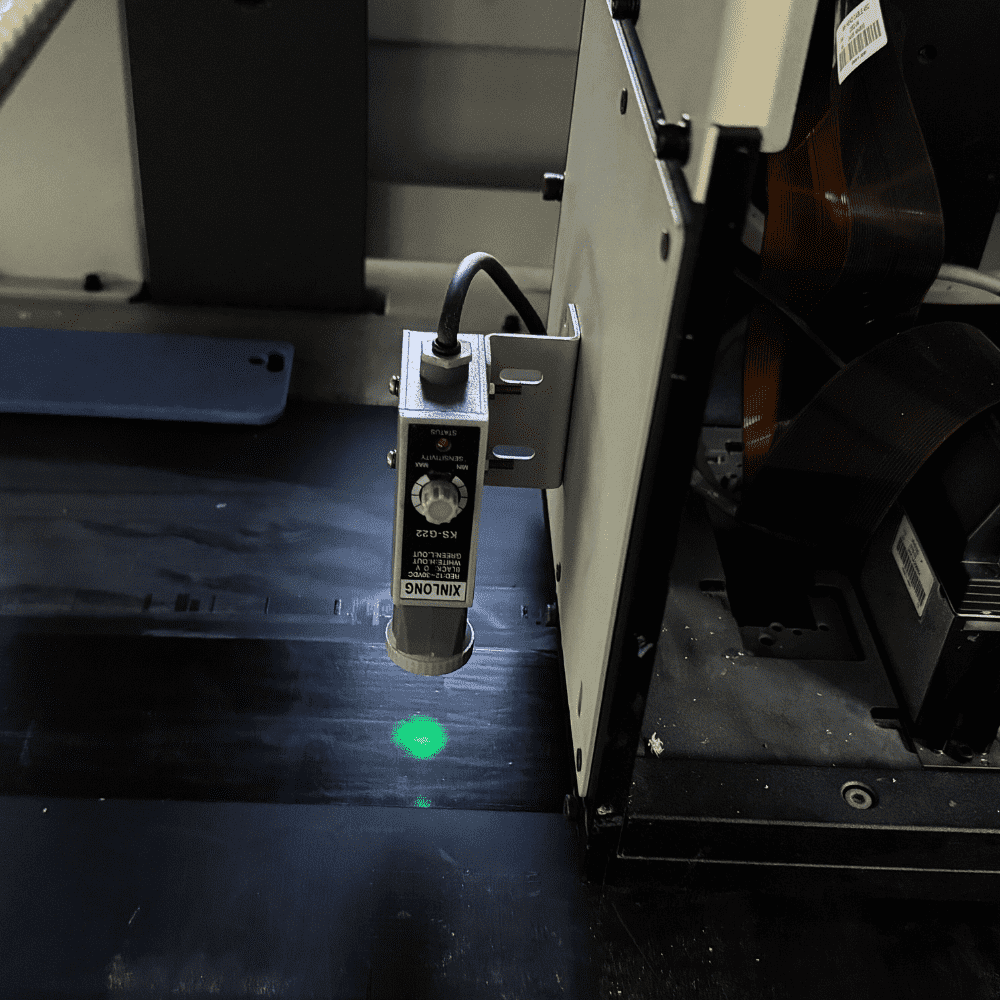

Automatically sense product identification and printing, accurate printing without misalignment.

The print head automatically returns to the printing height of last printing jobs.

High-power independent motor for suction platform, better adsorb soft products well on the flatbed, not easy to damage the print head.

Always control the temperature of the print head and UV lamp to prevent overheating and damage to the print head and UV lamp, making printing smoother.

Control the large diameter belt drive of the Y axis, printing is more stable and printing is more precise.

.png)

Support variable code installation Variable data editing software available.

.png)

Supports the installation of plasma to remove static electricity and dust, avoid dust clogging, and enhance color fastness.

Do you want to receive notifications about:

* You can cancel your subscription at anytime