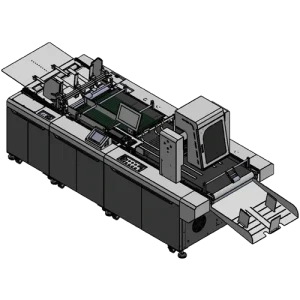

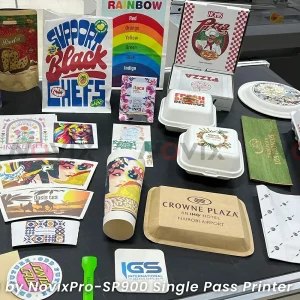

Breaking Through License Plate Frame Printing Bottlenecks: A Comprehensive Analysis of the One-Stop UV Single Pass Solution

Search Search Home / Product Series UV Single Pass Printer Series Single Pass Printer Series Contact Us Share this blog Facebook Linkedin Twitter You may