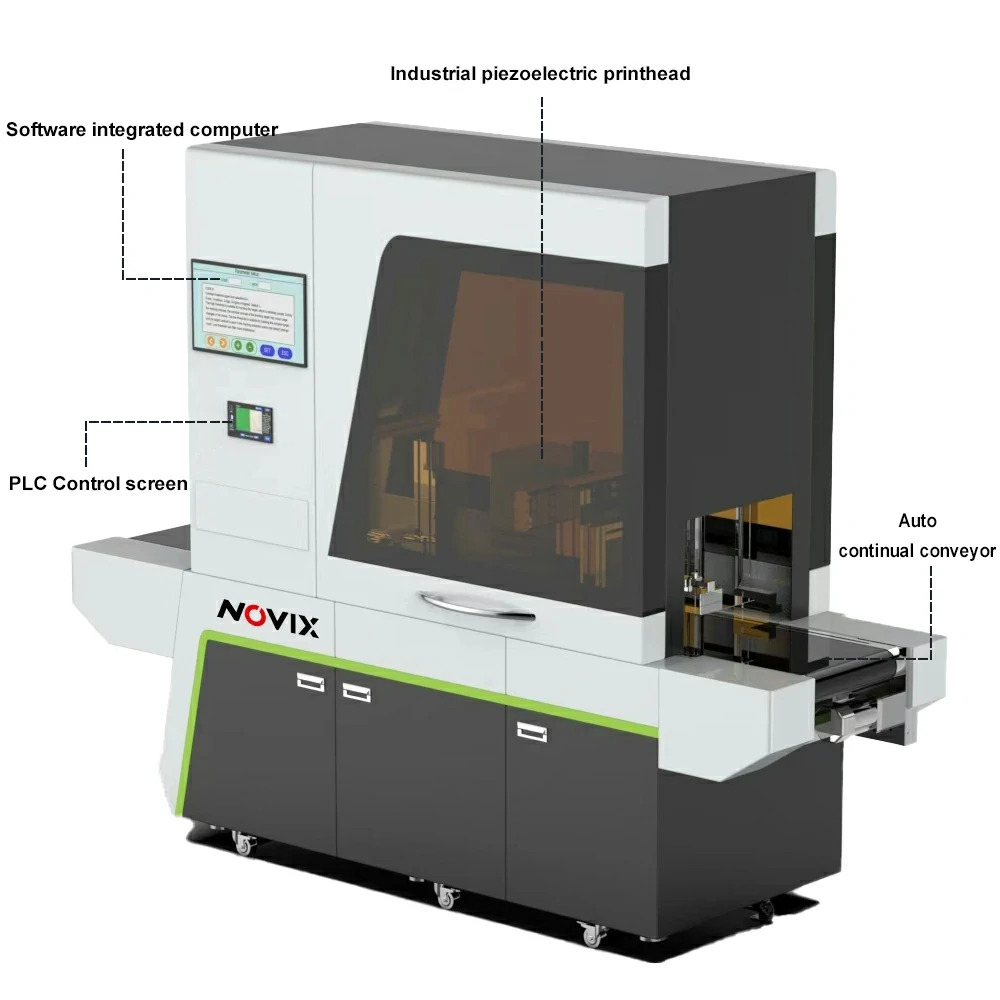

Industrial Side & Flat 2-in-1 Digital Printer

Industrial level, designed specifically for printing on the side of the product

Industrial level, designed specifically for printing on the side of the product

One machine, two printing modes! Designed specifically for printing on finished cups. Whether it’s a plastic, glass, or stainless steel thermos, printing on the side or top, a single UV single-pass printer brings you the latest high-speed, full-color single pass printing technology.

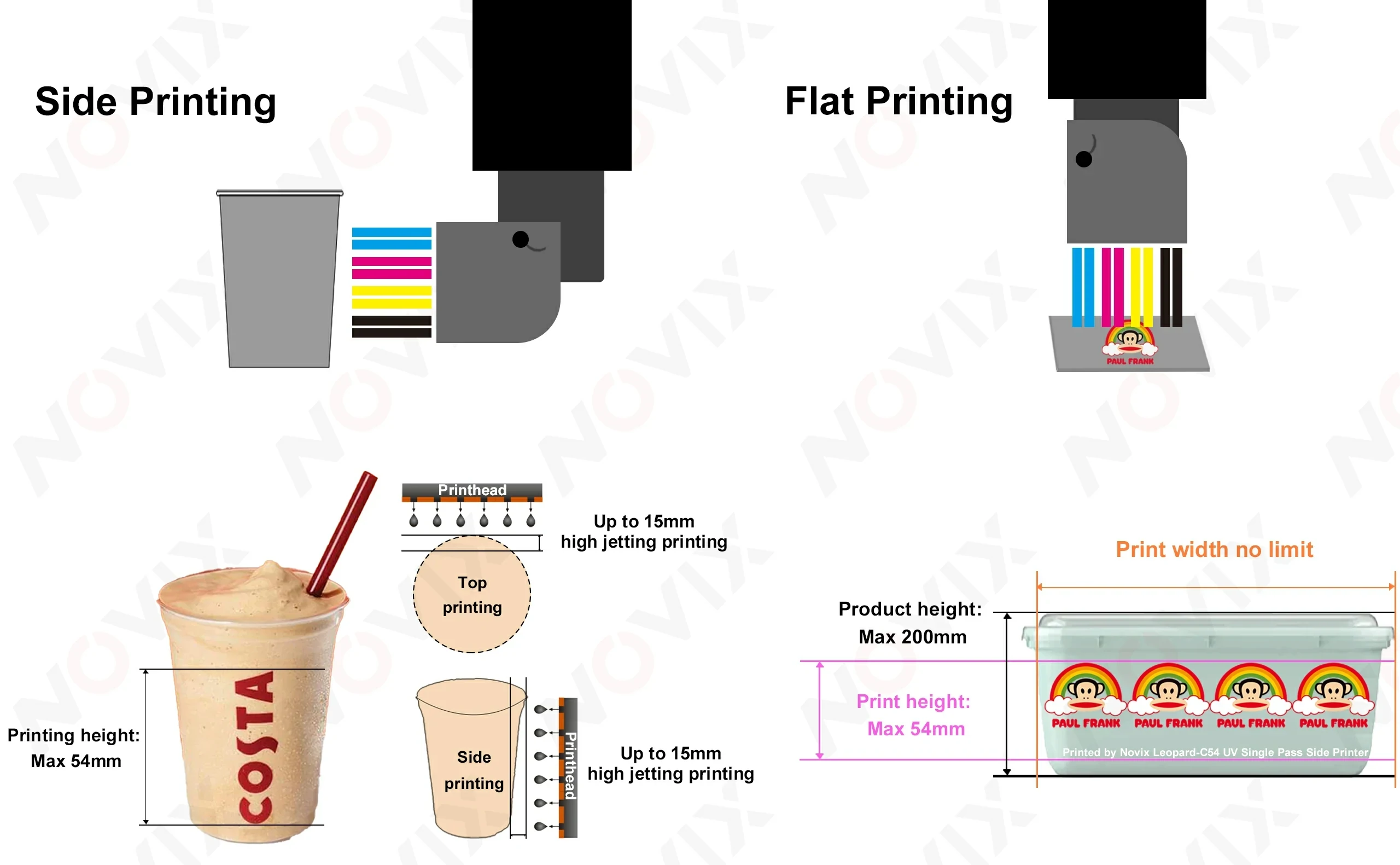

* Printing on Top/ Side 2 in 1 switchable printing

* High Speed: 1800~3600pcs cups/hour

* Direct CMYK: full colors printing on flat or curved surface

* Up to 15mm high jetting printing, better performance on curved surface

* Ink recirculation inside printhead, easier maintenance and longer printhead life

* Optional Automatic cups feeder/ receiving system customized available for different products, save labour cost

* Optional software for Variable data/ QR code/ barcode/ number/ letters/ matrix etc.

* Customized Plasma treatment to clean dust and increase color fastness on products

* More compatible ink, over 200 types of ink formula tested for better printing quality and color reproduction on different material

Revolutionizing the boundaries of printing: a cup, a moment, can be printed.

Revolutionary UV Single Pass printer technology brings you the ultimate digital printing experience

UV Single Pass Side Printer

Product

Screen Printer

Single color,CMYK+W multi colors,complex colors, gradient color

Multi-color direct printing

Only single color at a time, no gradient colors

4 steps: Graphics design -> Software/ Position Setting -> Printing -> Finish

Printing process

9steps: Graphics design -> Color Seperation -> Prepare screen(4steps) -> Ink modulation -> Printing -> Drying Process -> Finish

1 person

Labour needed

2-3person

54mm logo height, print width no limit on flat surface

Print size

logo size, limited sizes according to plates

Less hca sol vent use and waste water discharge.

Environmentally

friendly

The use of chemical solvents and wastewater discharge are high.

In the field of industrial-grade single-pass digital printing, the printhead is not only a core component but also the soul that determines production efficiency and output quality.

We perfectly combine high-performance industrial printheads with our UV single-pass printers to bring you the ultimate printing experience.

While achieving high-speed printing, it ensures excellent color performance. The combination of a high-precision inkjet system and optimized color management software enables the accurate and vibrant full-color images with natural transitions to be accurately presented on the sides of various cups and flat materials in a single print. Whether it is a complex gradient pattern or a delicate brand logo, it can achieve high fidelity and excellent visual impact.

Oil-based Single Pass UV ink with its non-VOC formula, significantly reduces its environmental impact, meeting increasingly stringent international environmental standards. green, safe, and harmless, protecting your health.

Every user’s product size, height, and printing needs are different. Novix has a professional technical team and engineers who can tailor a complete, intelligent, and automated printing solution to your specific needs.

Contact the Novix team now!

Dedicated research and development and excellent manufacturing quality give you a unique and reliable digital printer, empowering your brand/products.

This large-format, high-performance computer-integrated printer comes pre-installed and tested with software, and the Novix team can remotely access the computer for assistance.

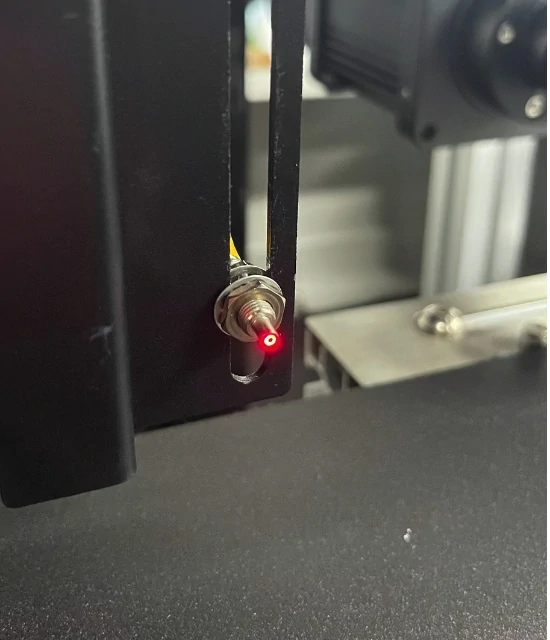

Precise identification of the media location ensures more accurate printing.

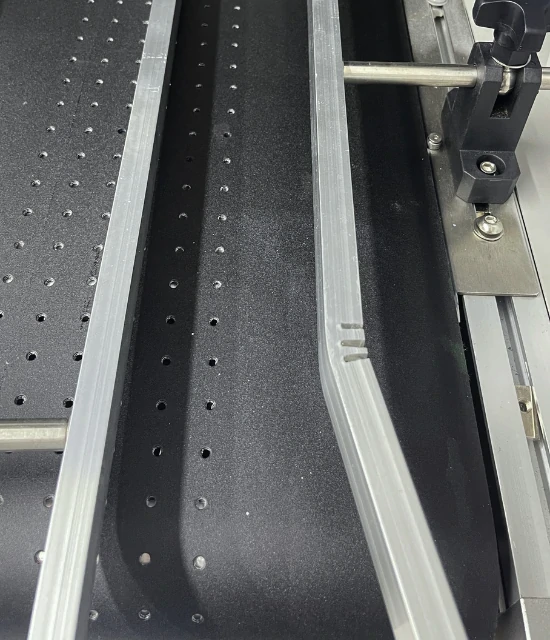

CISS ink supply system, more

stable and less easy to cause bubble in the printheads.

For better ink fluency and stable printing.

Easy to adjust, suitable for printing of products of all sizes. Material width supported up to 400mm.

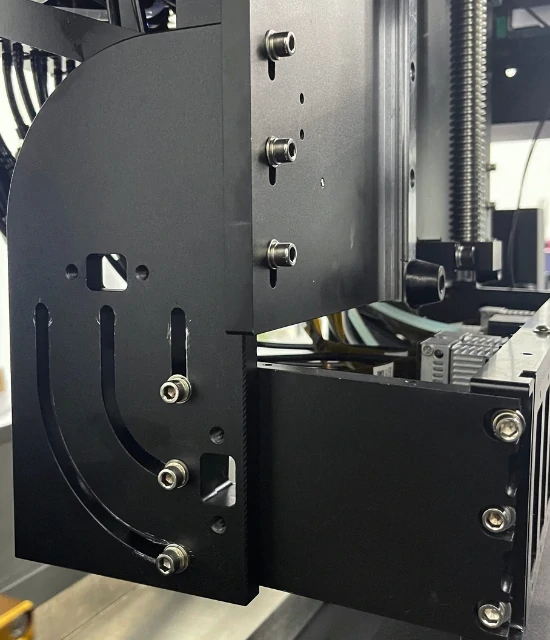

A single printer can perform both side and flat surface printing; by adjusting the print head position as needed, it can achieve two functions in one machine.

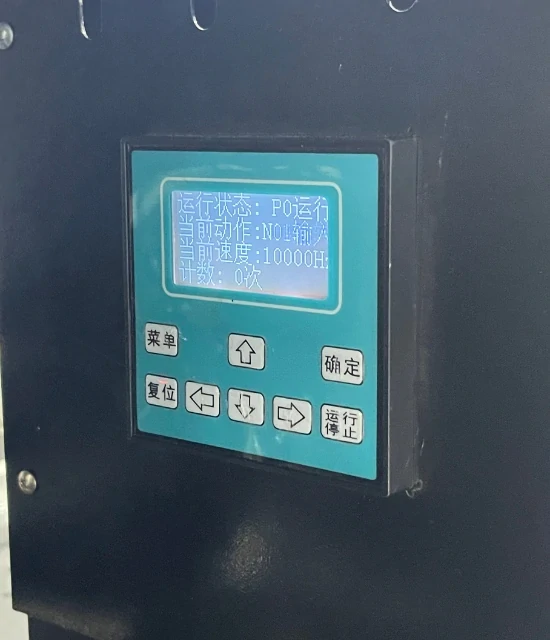

One-button control allows for simultaneous up, down, left, and right movement of the printhead, as well as reset, stop, and other operations. Operation is extremely simple, allowing for easy control of the entire machine.

Good products are revealed in the details.

| Print head | Industrial piezoelectric printhead |

| Technology | MEMS/ POD technology |

| Ink recirculation | Ink recirculation through all channels |

| Printhead life | Piezoelectric Drive durability, more than 106 billion inkjet times |

| Greyscale | Greyscale levels printing |

| Nozzles Resolution | 300npi (2 color/head)/ 600npi (1 color/head) |

| Number of nozzles | 639nozzles (2 color/head)/ 1278nozzles (1 color/head) |

| Temperature control | Build-in temperature sensor |

| Jetting frequency | 12kHz / 3drops |

| Printhead Protection Technology | Auto carriage/printhead anti-scratch kit |

| Maximum printing thickness | 0-200mm (Printing height customization available) |

| Printing width(mm) | 54mm logo height, print width no limit |

| Material width(mm) | 400mm |

| Print Speed | Single color: 0-120m/hrs;Multi-color: 0-40m/hrs |

| Flatbed Type | Auto continual conveyor |

| Media Release device | Manual feeding/ customized feeder *Optional |

| Media Take up device | Take up tray *Optional |

| X axis adjustment | Quality linear rails + Ball screws |

| Z axis adjustable | Button & manual adjustment available |

| Control syetem | Novix Single Pass Control software, pre-installed in integrated computer on machine |

| RIP Software | RIIN software with color management (With ink consumption/ cost auto calculation) |

| Remote control software | Pre-installed in integrated computer on machine |

| Other option | Software interface secondary development available |

| Variable data editing software available | |

| I/O Interface, robot controlling conection support |

| Ink type | Oil-based Single Pass UV ink (Non-VOC) |

| Color Configuration | Single color; Multi-color;Spot color customization Cyan(C), Magenta(M), Yellow(Y), Black(K), White (W) |

| Ink supply | Continual ink supply system (CISS); Intelligent constant sub-ink tank pressure |

| Ink filter | Ink filtration system available to filtering oversized particles |

| Ink tank | 2500ML/color |

| Protection system | Automatic ink shortage alarm system, support ink refilled during printing |

| Anti clogging of Printhead | Automatic white ink stirring system; nagative pressure ink control |

| Cleaning & Maintenance system | Automatic cleaning ink station, auto flashing and maintanence |

| Temperature | 15℃~ 30℃ (59ºF~86ºF), Humidity 30%-70% |

| Voltage | 220V/AC(±10%), 50/60Hz, 1KW(Max.) |

| Acoustic noise level | 70db(A) or less |

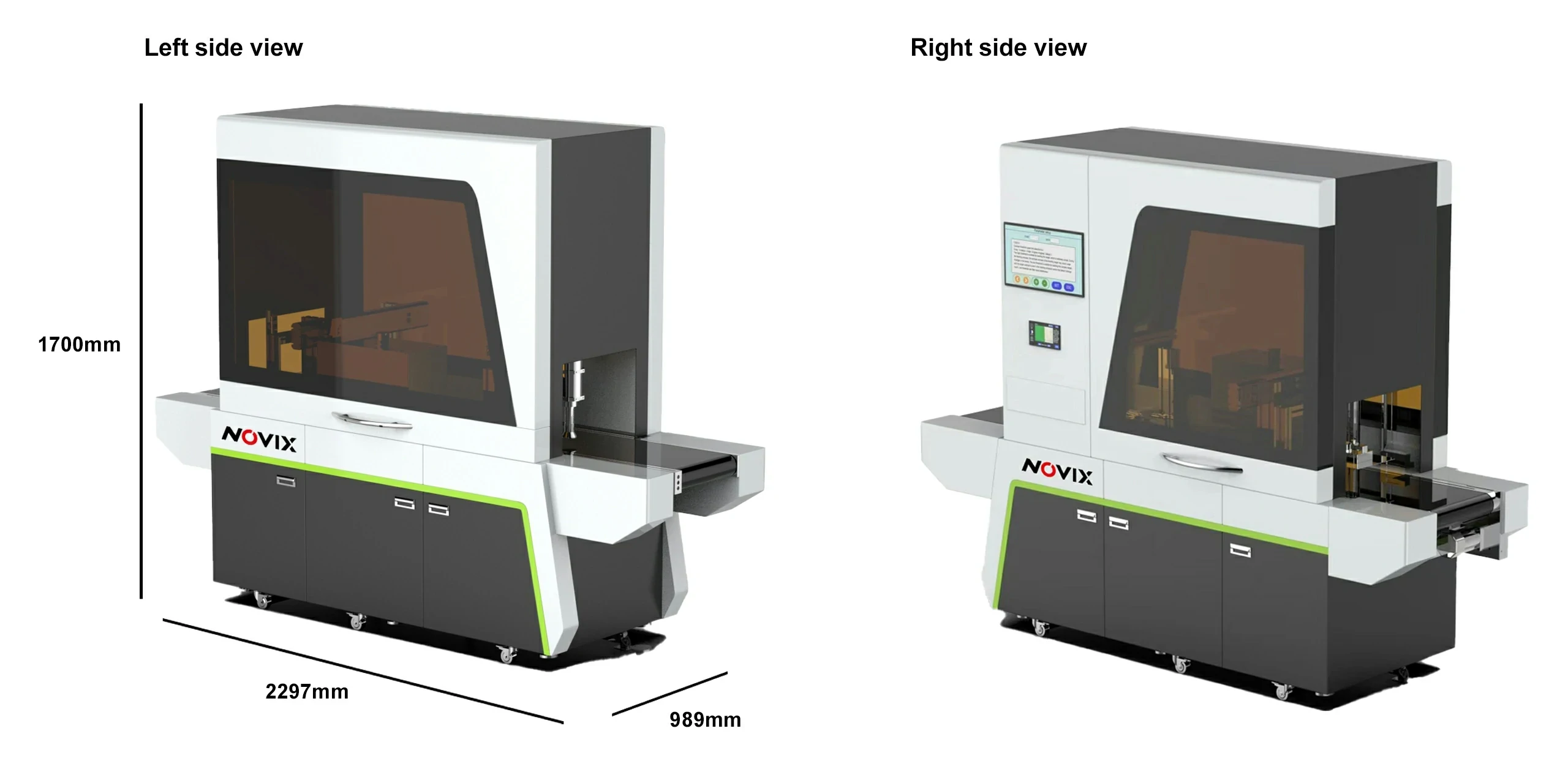

| Printer size(L*W*H) | 2297*989*1700mm |

| Package size(L*W*H) | 2500*1000*1900mm |

| Net Weight of printer | 560KG |

| Gross weight | 640KG |

| Package type | Inside foam protection, outside Ply-wood steel frame package |

| Operating system | Windows® 10 (64 bit) Recommend |

| CPU | Intel® Core™ i5, 2.5 GHz or more |

| HDD | Install space 1 GB or more; Working space 100 GB |

| Processor prefered | INTEL AMD |

| Storage | RAM>8G |

| Data Interface | Gigabit Ethernet port |

The UV Single Pass Cup Side printer is a revolutionary digital printing solution that precisely combines the extreme speed of “Single Pass” printing with the broad material adaptability of “UV curing.” It not only solves the challenge of high-speed, high-quality printing on rigid curved surfaces but also maximizes the potential of a single device through innovative convertible printing modes. Choosing it means choosing high efficiency, low cost, and unlimited creative freedom, helping you stand out in the personalized customization market.

UV printers require the print head to move back and forth multiple times to complete a print, while our UV Single Pass technology allows the print head to complete the printing of the entire cup side pattern in a single pass. This represents a leap from “slow drawing” to “instant imaging,” increasing printing speed by more than 10 times.

It can print directly on most rigid materials, including PET plastic cups, glass cups, stainless steel insulated cups, ceramic cups, etc. Thanks to its powerful UV ink and instant curing technology, most materials require no pretreatment or coating, truly enabling instant printing, saving time and effort.

A major highlight of this machine is its flexible “dual-mode” design. Through a simple mechanical switch, printing can quickly transition from side printing to flat surface printing, perfectly suited for printing on cup tops, acrylic, license plate frames, metal, and other flat objects, expanding your business scope.

Speed is its core advantage. Taking printing a full-width pattern on the side of a cup of typical height as an example, the printing cycle time for a single cup can be as short as a few seconds. Combined with an automatic feeding system, continuous and efficient mass production can be achieved, with capacity far exceeding traditional methods.

We have designed an intuitive software interface that operators can master after a short training period. The automatic printhead maintenance system and modular design make daily cleaning and replacement of key components very simple, maximizing the stable operation and high utilization rate of the equipment.

Novix team is dedicated to research and development, striving to bring you the smartest, most convenient, most suitable, and most cost-effective printing solutions to empower your brand.

Do not hesitate to reach out. Just fill in the contact form here and we’ll be sure to reply as fast as possible.

Room 105, Tower B, Tianhui Building, No. 29, Yeqin 1st Road, Longgang District, Shenzhen, Guangdong, China

info@onepassprinters.com

+86 13302697226

Do you want to receive notifications about:

* You can cancel your subscription at anytime