Advantages

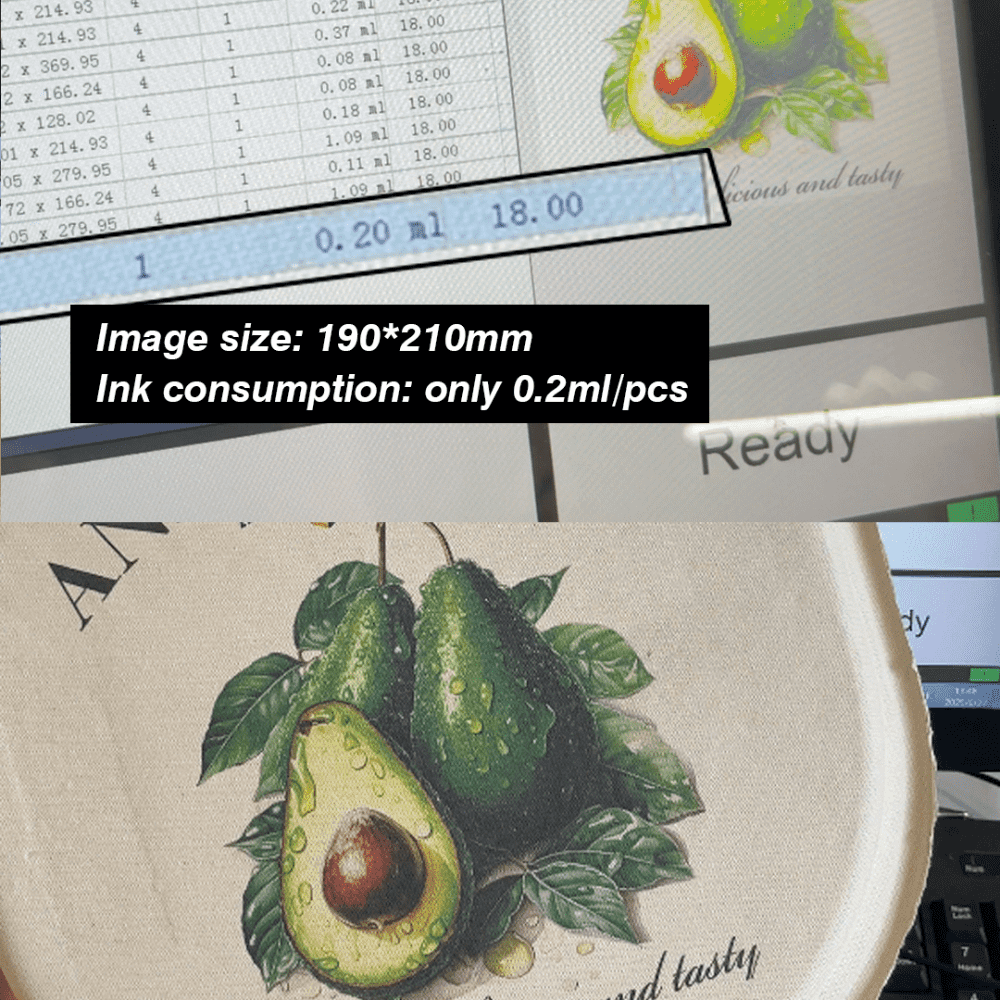

1. Printing cost as low as $0.02/㎡

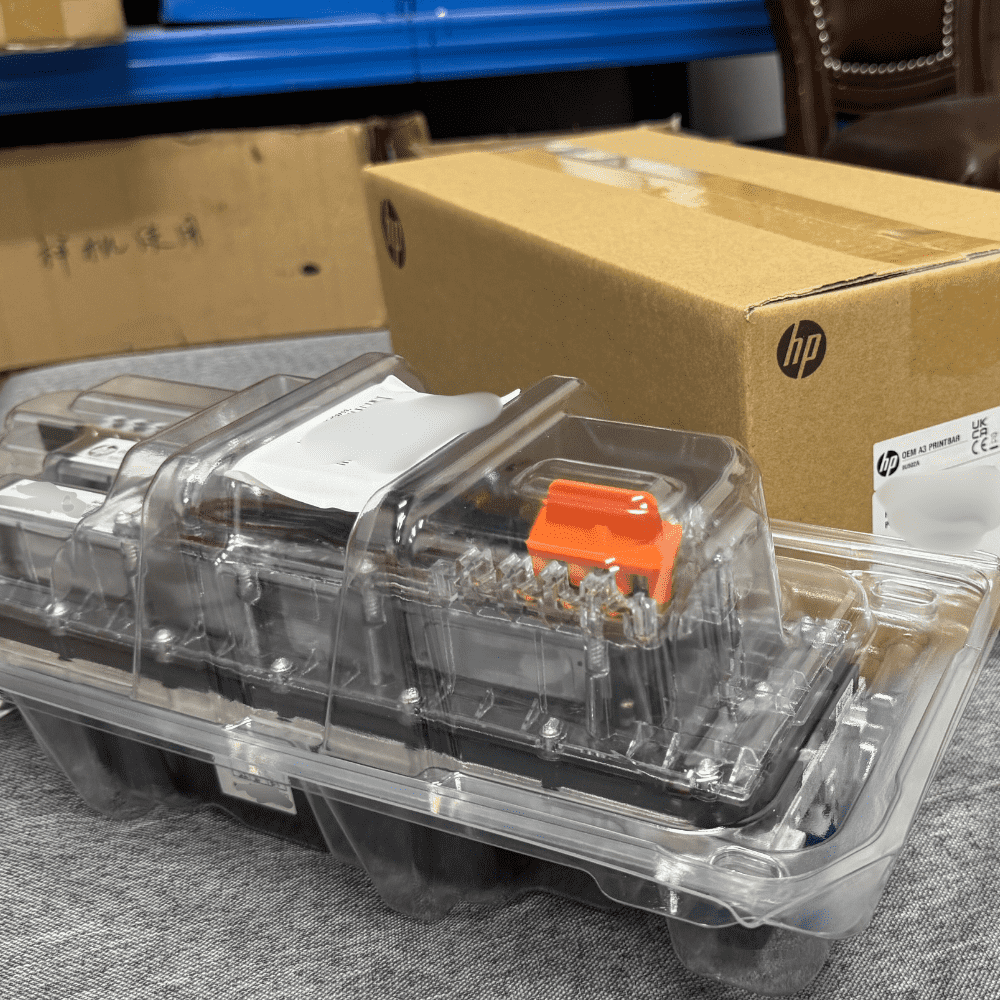

2. HP widepage industrial printheads, support different printing width.

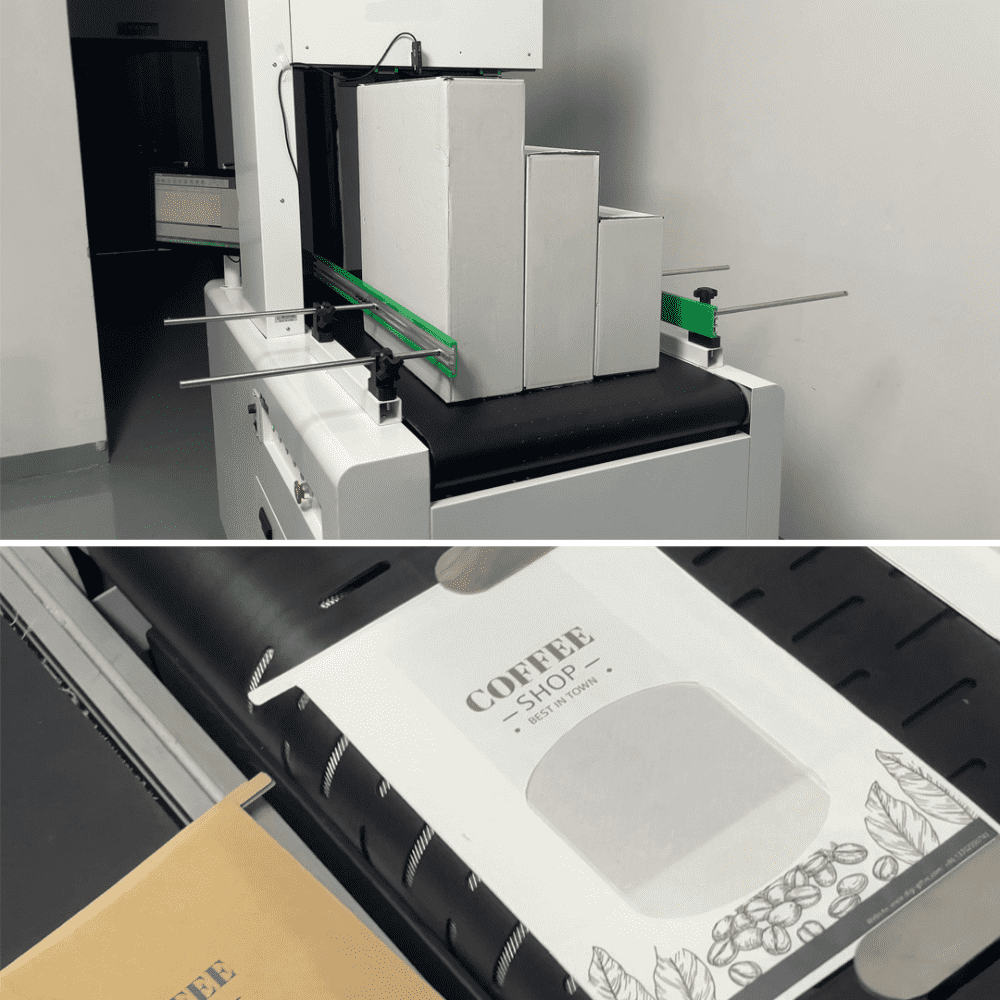

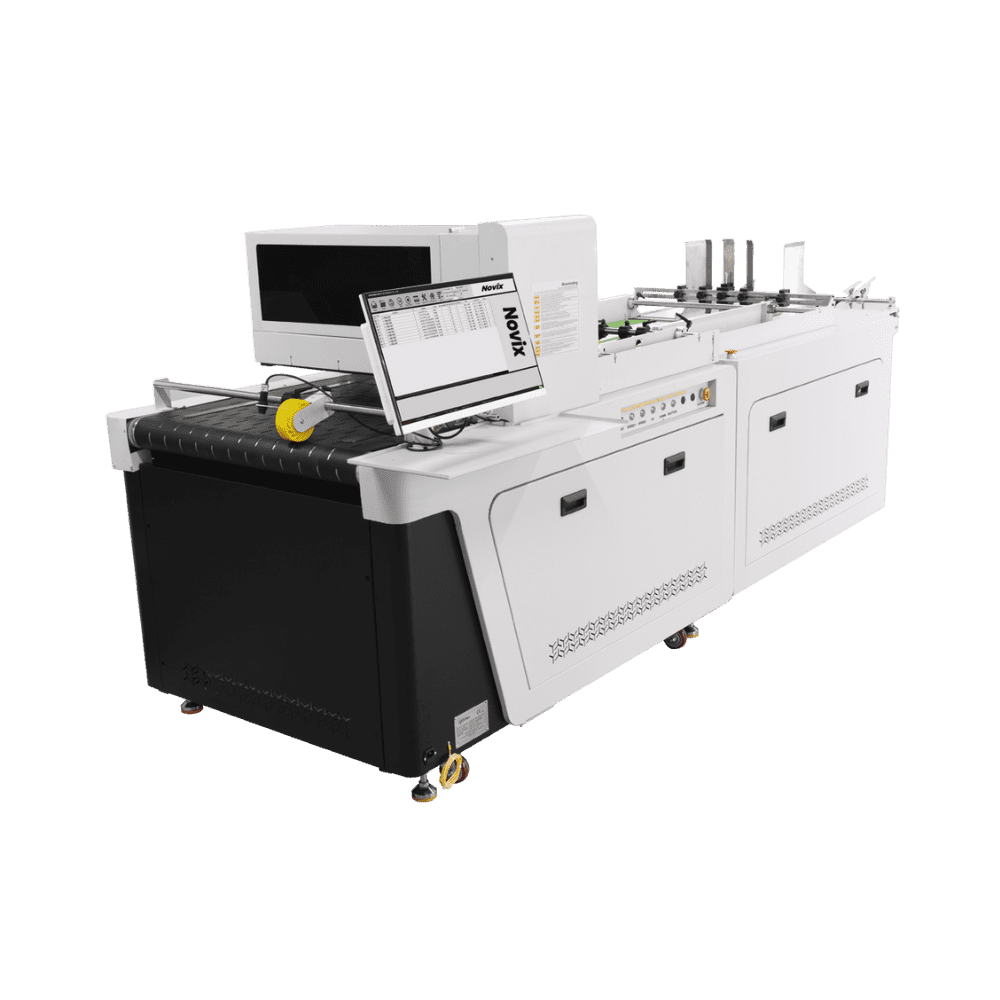

3. Save labour cost, automatic belt convayor with vaccume table, continous high-speed printing

4. Light-weight smaller industrial design, easy to move and operate, save space.

5. More flexible, size customization available, to meet the demands of your small or large batch production, without complicated platemarking process.

6. Fast drying water-bsaed environmentally friendly ink, ink dries immediately after printing, pattern is waterproof and anti-fouling after printing.

Application

Corrugated boxes, pouch, paper cup, catons, napkin, kraft paper bag, gift bag, tissue, carton, handbags, packaging boxes, brochures, booklet, egg box, labels, cards, pizza box, shopping bags etc…

Water based ink-absorbing material

| Printer color | Black / White |

| Printer name | Single Pass Printer |

| Maximum printing thickness | 7.82 in. (200mm) |

| Flatbed Type | Vacuum adsorption, auto continual conveyor |

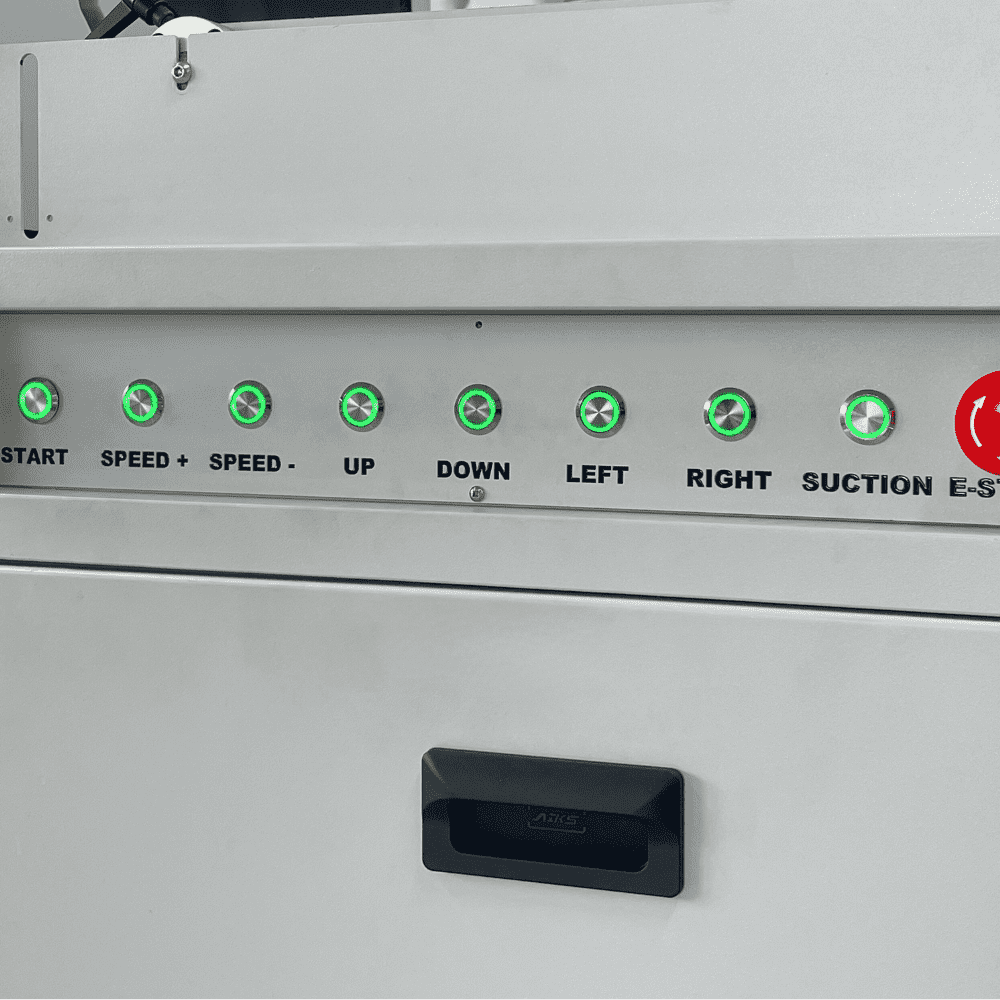

| Control syetem | Touch screen control panel |

| Media Release device | Integrated friction feeder *Optional |

| Media Take up device | Adjustable take up tray *Optional |

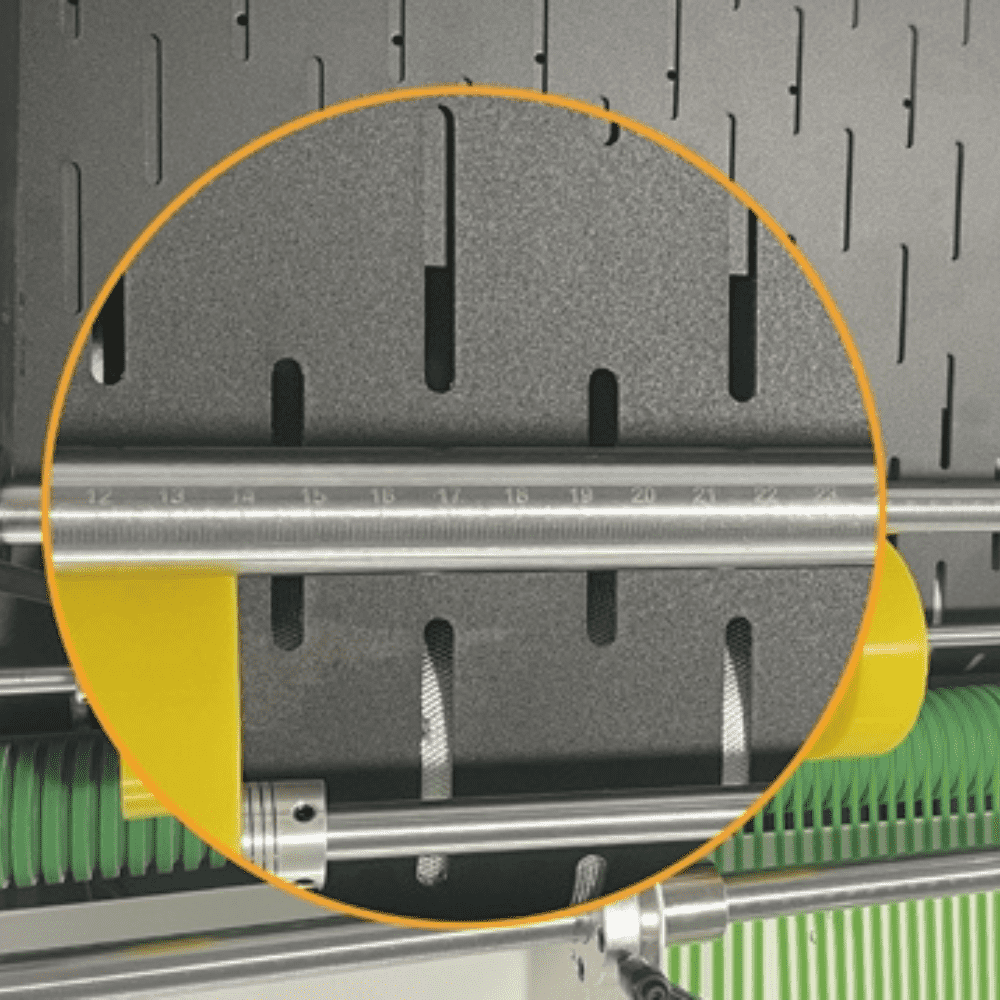

| X axis adjustment | Dual leadscrews, automatic & manual adjustment |

| Printhead quantity | 1~3pcs * HP widepage industrial printheads (bigger size customization support) |

| Model name | Leopard-S300 |

| Printing width(mm) | 300mm (11.81”) |

| Machine for Material width(mm) | 600mm (23.62”) |

| Technology | Advanced thermal foaming bubble-inkjet technology |

| Ink drop Volume | 6PL |

| Print head | 1~3pcs * HP widepage industrial printheads |

| Resolution | 1200*300dpi, 1200*600dpi,1200*1200dpi |

| Print Speed | 10-30m/min |

| Printhead Protection Technology | Auto carriage anti-scratch kit |

| Ink type | Aqueous/ dye/ pigment water-based ink |

| Color Configuration of printing | Cyan(C), Magenta(M), Yellow(Y), Black(K) |

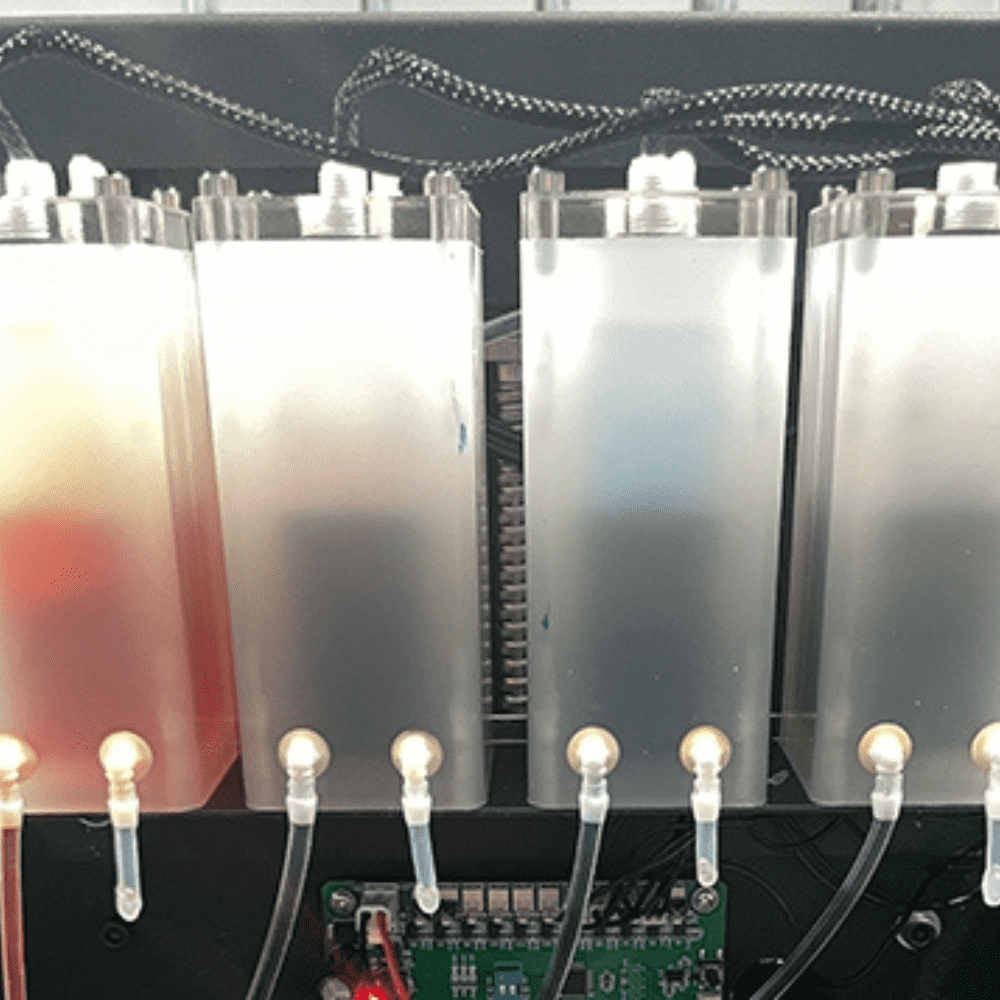

| Ink tank | 1500ML/color |

| Ink supply | Continual ink supply system (CISS); Intelligent constant sub-ink tank pressure |

| Temperature | 15℃~ 30℃ (59ºF~86ºF), Humidity 30%-70% |

| Voltage | 220V/AC(±10%), 50Hz, 1KW(Max.) |

| Acoustic noise level | 70db(A) or less |

| Printer size(L*W*H) | 1510*840*1280mm (Main printer) |

| Package size(L*W*H) | 1700*1000*1400mm (Main printer) |

| Net Weight of printer | 200KG |

| Gross weight | 265KG |

| Package type | Inside foam protection, outside Ply-wood steel frame package |

| Operating system | Windows® 7/10 (64 bit) Recommend |

| CPU | Intel® Core™ i5, 2.5 GHz or more |

| HDD | Install space 1 GB or more; Working space 100 GB |

| Processor prefered | INTEL AMD |

| Storage | RAM>8G |

| Data Interface | Gigabit Ethernet port |

·1 person to operate, no technical skill needed.

·Image import software, direct printing

·No minimum order quantity, you decide how much to print.

·Supports CMYK direct printing of different patterns at the same time.

·Print speed: 10-30m/min;Adjustable speed, one print per second.

·Reduce printing costs and increase your profits

·For printing of different product sizes, NOVIX can match the most suitable packaging printing solution for you.

·According to your printing order requirements, we support pigment or dye inks, just to give you the best printing color and experience.

·Environmentally friendly ink, ink dry immediately after printed, no need to wait

UP to 1200dpi Resolution, accurately restore color saturation

Let your pattern be realized on the product

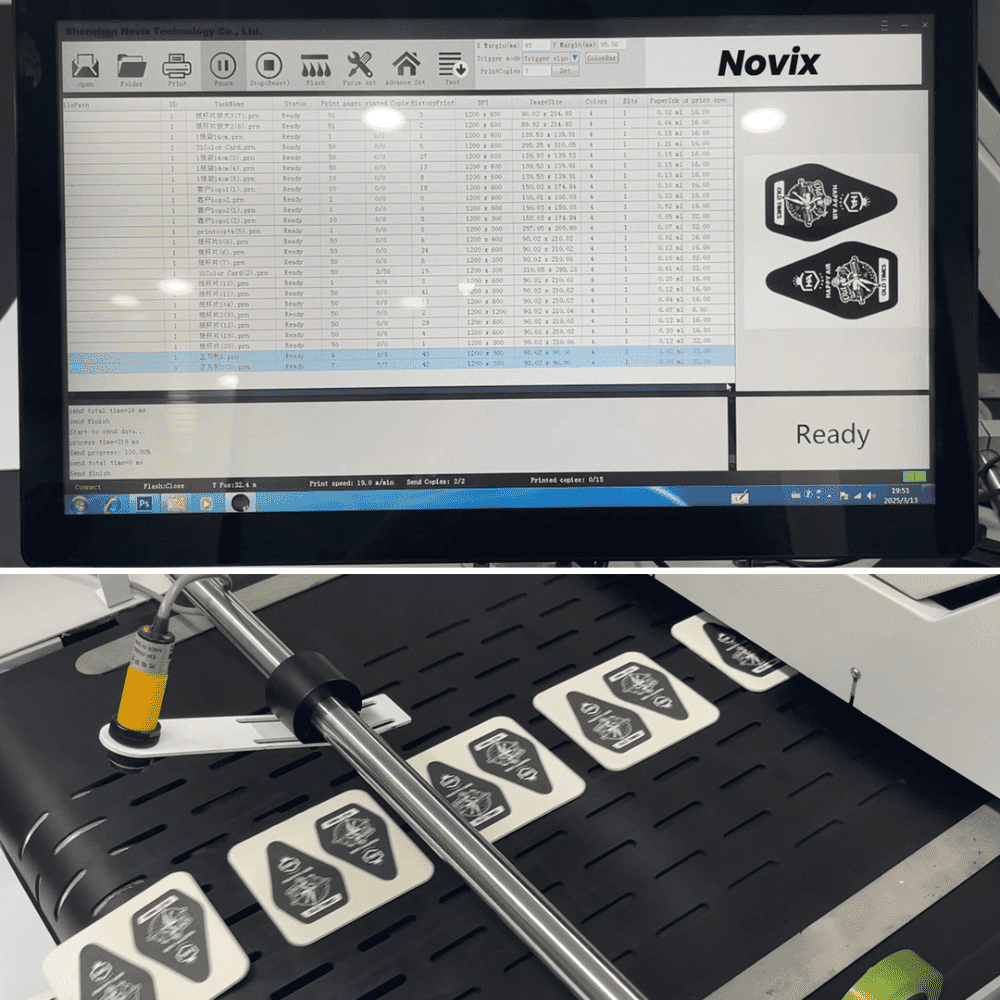

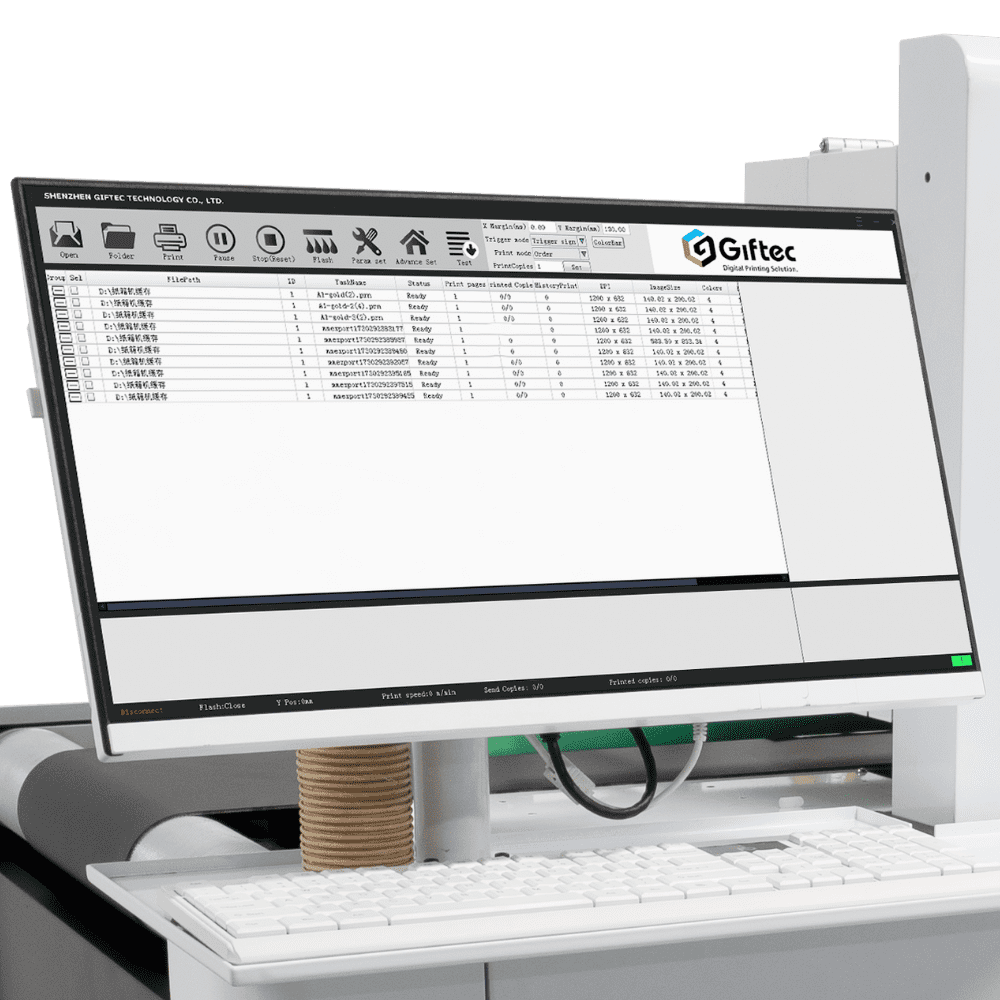

Novix upgraded Control software & RIP color management all in one output software, intelligent color management, accurate control, good color reduction, simple and clear interface, easy human-machine interaction and simple operation.

Rich and diverse product customization brings you rich business and profits

Good products are determined by details

Super 24 inch computer integrated with printer, software pre-installed and tested, Giftec team can access the computer to remote assist.

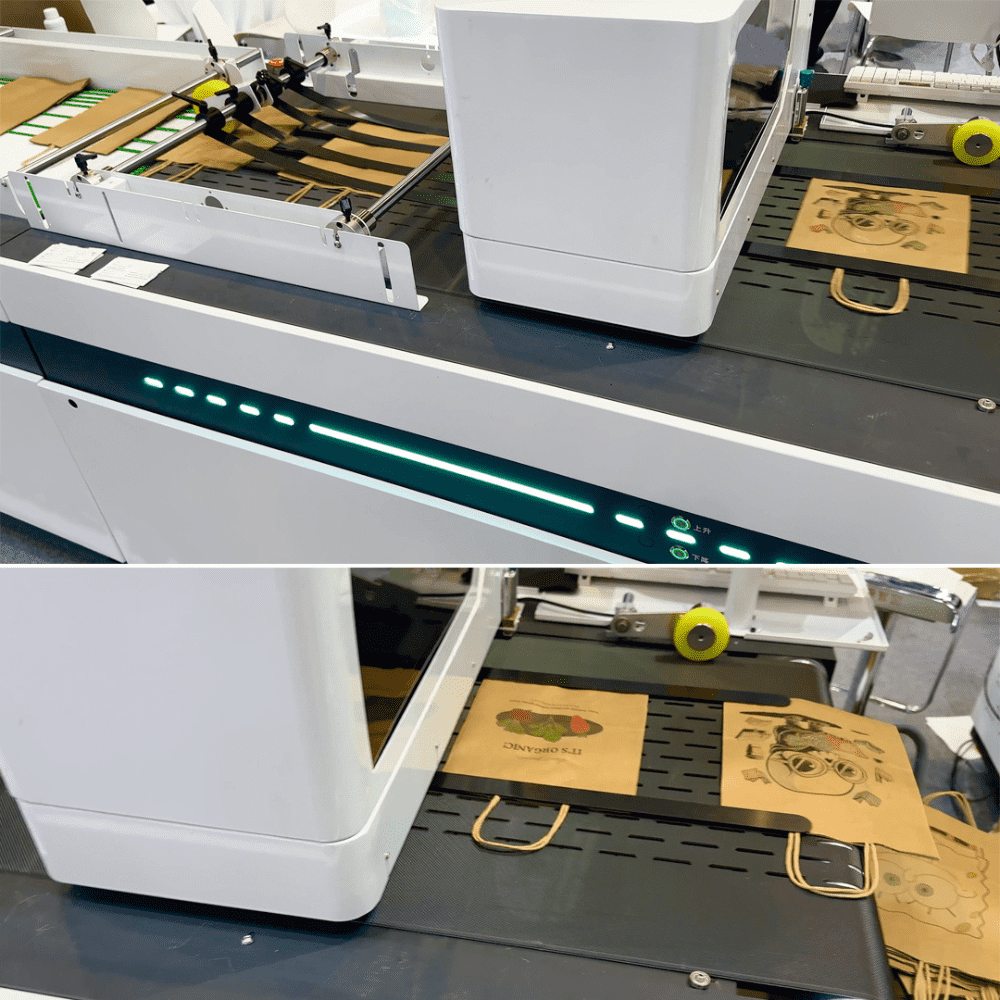

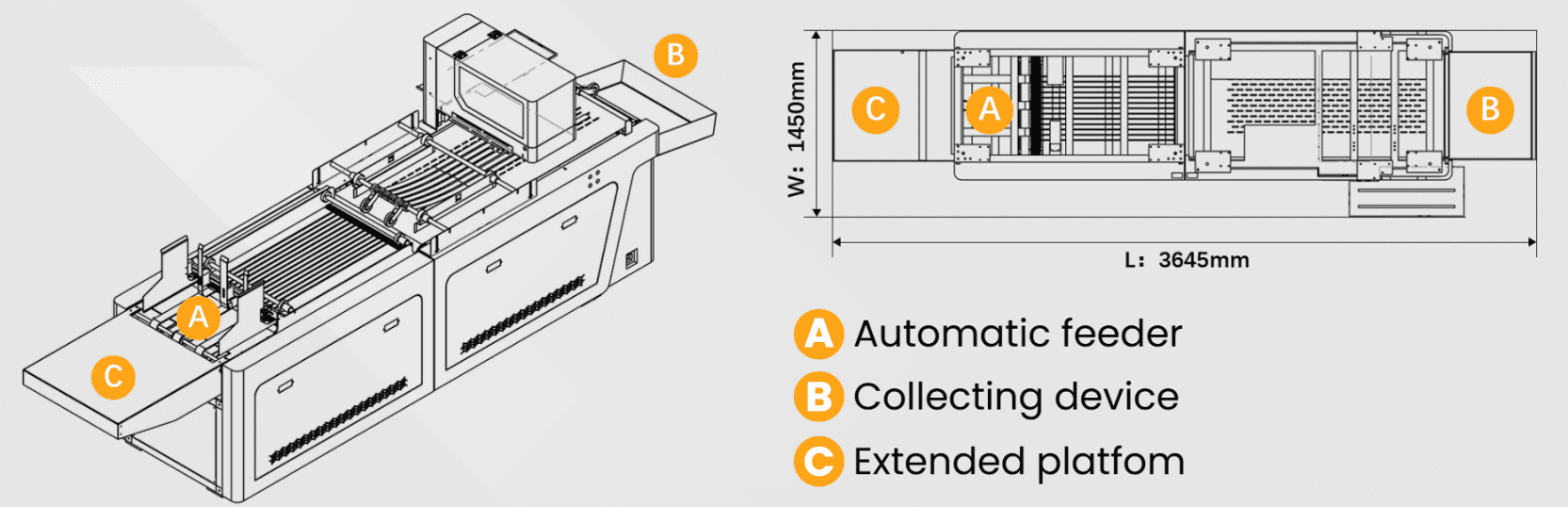

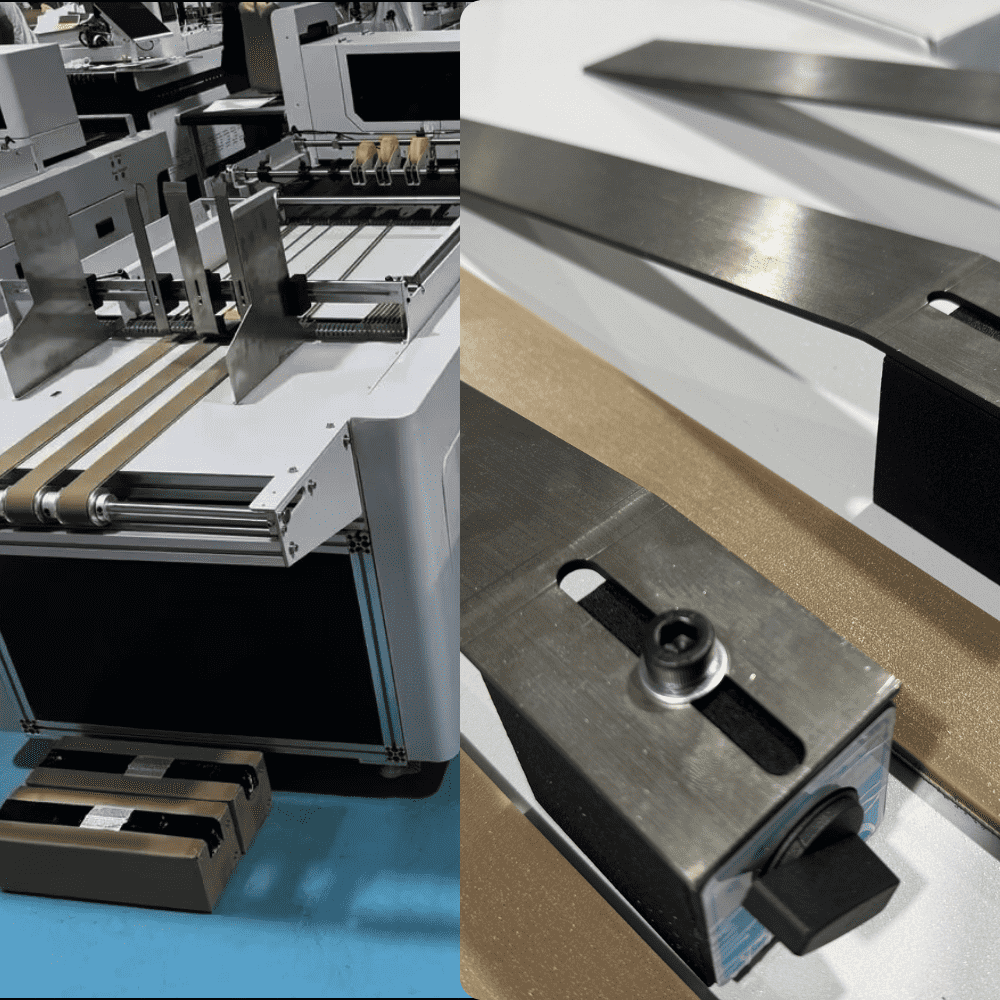

Auto feeder + Magnetic feeder aid

Automatic feeding machine,friction feeder.suction feeder,baffle feeder for different material feeding, please contact Giftec team to help you choose the most suitable printer and feeder solution.

Flexible side baffle to help feeding all material printed on same position.

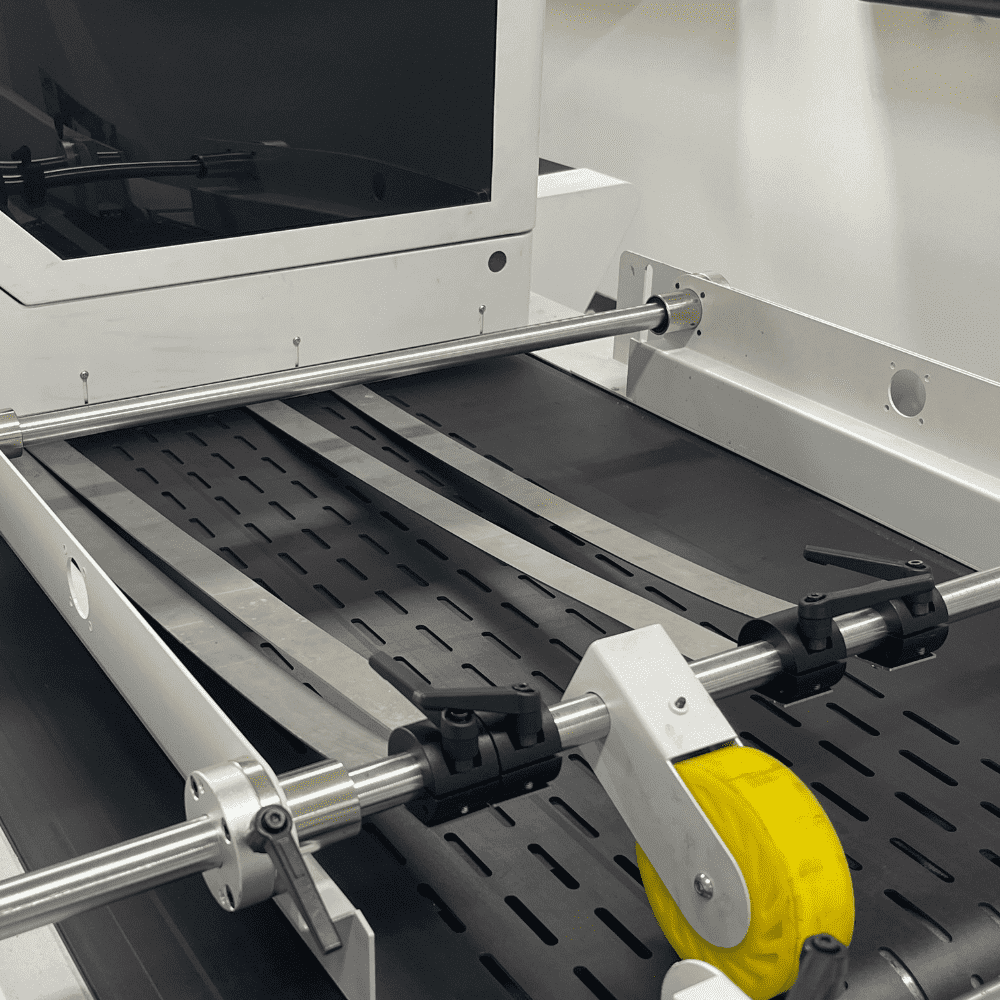

Pressing wheel and pressing stripe to make sure material printing without scratching printhead.

The scale is easy to adjust the position of the pressing stripe and pressing wheel to position the product.

One-button START control sync speed printing for Speed UP and DOWN, amazingly user-friendly to control the whole machine

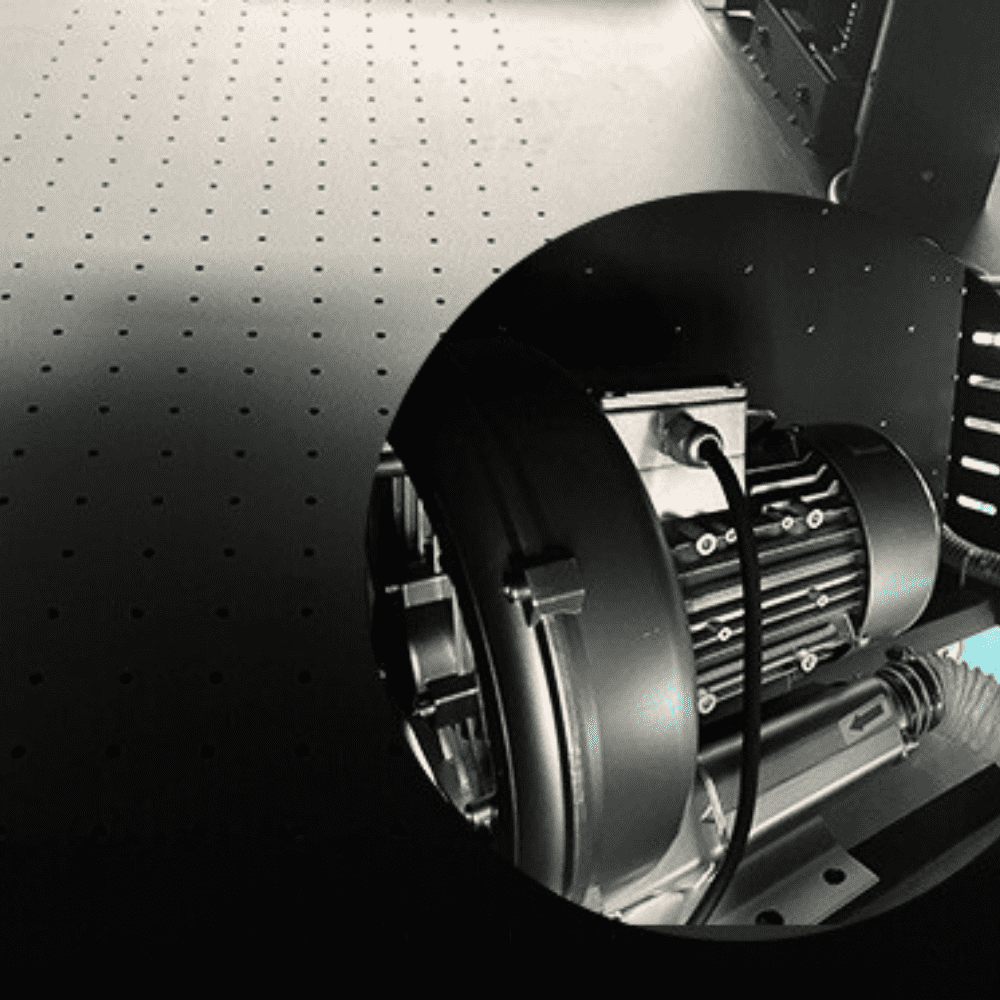

500W high-power independent motor for suction platform, better adsorb soft products well on the flatbed, not easy to damage the print head.

-1.png)

Optional receiving tray to count and receive materials by stack according to the required packaging quantity, saving labor costs and improving efficiency.One person can easily operate the printer.

Sub-inktank CiSS ink supply system, more stable and less easy to cause bubble in the printheads.

For better ink fluency and stable printing.

Do you want to receive notifications about:

* You can cancel your subscription at anytime